- About Us

- Products

- All Plastic Packaging Products

- Industrial Shrink Film

- Shrink Film

- Flxtite® AP-1 Non-Irradiated Polyolefin Film

- Flxtite® AP-6 Forming Film

- Flxtite® AP-X Cross-Linked Shrink Film

- Flxtite® AP-XF Anti-Fog Polyolefin Film

- Flxtite® AP-XGR

- Flxtite® AP-XH Heavy Duty Shrink Wrap

- Flxtite® E-1 Polyethylene Shrink Film

- Ecolene® AP-XEC Biodegradable Shrink Wrap

- Ecolene® AP-XPCR PCR Packaging Film

- Solutions

- Case Studies

- Blog

- Contact

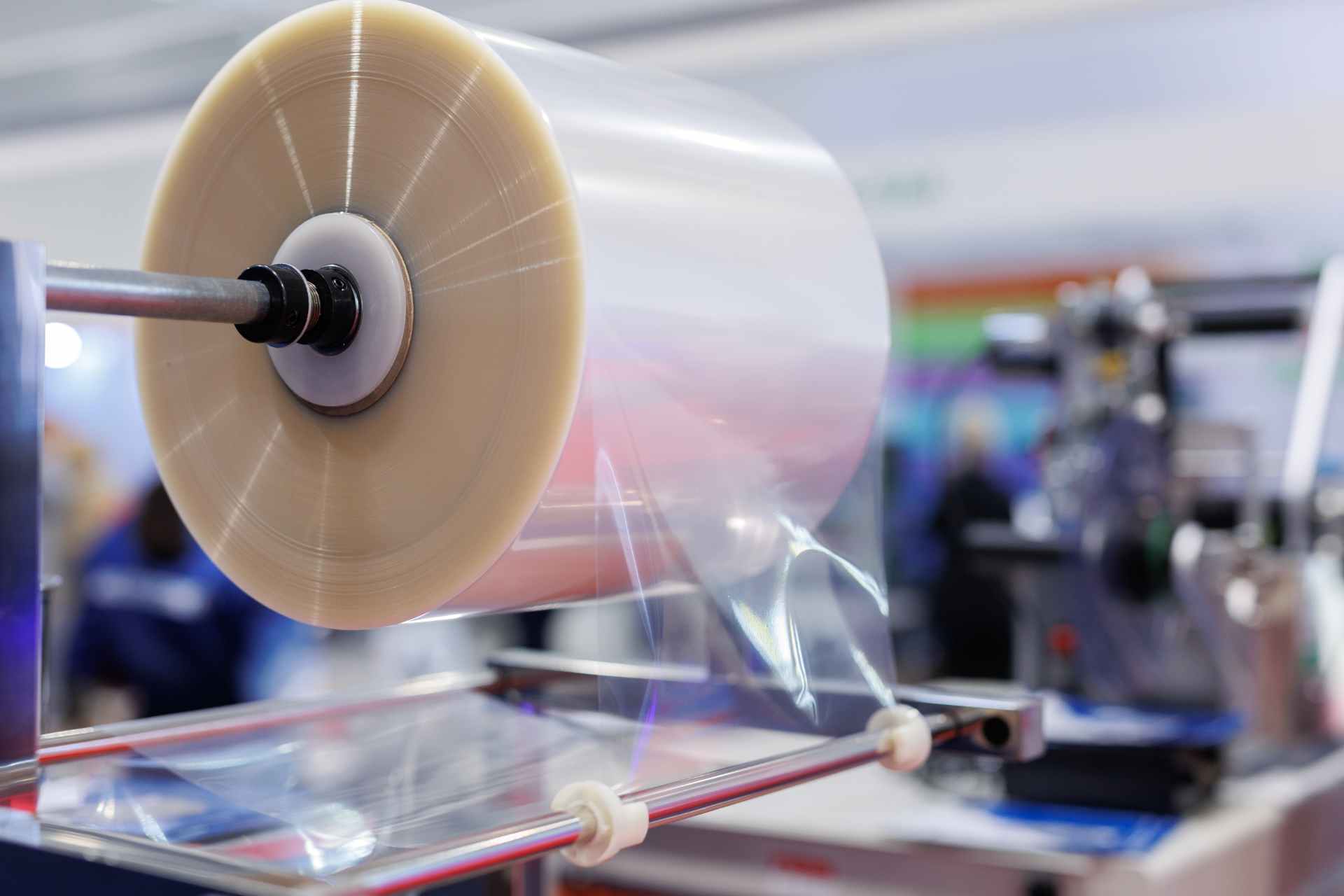

Upgrade your Food Packaging with Crystal Clear Polyolefin Shrink Film

The food industry is highly competitive, and often, the best-packaged brand wins the sale. Upgrade your food packaging with a high-gloss, high-clarity premium polyolefin shrink film.

Studies show that consumers perceive items packaged in glossy shrink film as premium products. They are more likely to purchase shrink-wrapped products over competitors and are willing to pay a higher price for the higher perceived value. Whether you’re packaging fresh produce, frozen pizza, or meat and poultry, take your food packaging to the next level with a high-quality POF shrink film.

Why Food Packaging Companies Choose Flxtite® Polyolefin Film

Polyolefin film is the highest-quality film on the market with a number of food packaging benefits. Here’s why many companies choose shrink film over traditional food packaging supplies like boxes, containers, and trays.

Protects food items from dust, dirt, and contamination

Prolongs shelf life

Allows for easy bundling of multipacks or promotional offer items

Enhances shelf appeal

360-degree product display

Space-efficient maximizes pallet and warehousing space

Rightsized to eliminate wasteful packaging

Tamper evident

Fully Customizable Food Packaging Supplies

We place our customers at the center of everything we do at Folene Packaging, and we are 100% committed to your packaging success. We offer all of our rolls in both center wound and single wound sheeting to deliver the product that works best for your production line. Want to make a marketing statement with your logo and branding on the package? We print custom orders in up to six colors. Want it pre-perforated for food service applications? Just let us know. Looking for specialty packaging? Tell us what you need, and we’ll be happy to help accommodate your request.

Case Study: Flxtite® AP-1 As An Excellent Alternative to Cryovac® Food Packaging Film

After an impressive test run, a Maryland-based seafood packaging company switched from Cryovac MPD 2055 high-speed film to Flxtite® AP-1. They were pleased with the significant cost savings and delighted with the film quality and seamless transition. Flxtite’s AP-1 acted as a perfect drop-in, not requiring any equipment adjustments, and their entire test pallet ran smoothly without any incident.

Optimize Product Appearance with the Right Packaging on Food- Even at Low Temperatures

Getting the packaging on food just right is a challenge for manufacturers. This challenge is highlighted in refrigerated environments, where additional moisture can cause fogging and obscure the product from view. Flxtite® AP-XF Crosslinked anti-fog film is specially formulated for packaging fresh produce, meats, poultry, and dairy in a refrigerated or freezer setting. It maintains excellent clarity and gloss even at low temperatures. Its performance successfully competes with all irradiated and cross-linked polyolefin shrink films, with great strength and shrink force.

A Ravioli manufacturer was packaging their products in clear polystyrene tubs, which were shrink-wrapped in conventional shrink film. However, when the package was placed in the freezer, the warm moisture caused the package to fog up, leaving the product not looking as appealing as expected. The manufacturer tested a roll of Flxtite® AP-XF, which immediately eliminated the fogging issue. They now successfully use a 60 gauge center-folded Flxtite® AP-XF, which retains its clarity and gloss in the stores’ freezer shelves, improving shelf appeal.

Eco-Friendly Food Packaging

Folene Packaging is a member of the Sustainable Packaging Coalition. We believe that food packaging manufacturers have a responsibility to the environment and our customers to do more to support a sustainable food packaging industry. We are committed to providing eco friendly food packaging solutions that benefit our customers, food packaging companies, and the Earth. That’s why all of our non-irradiated polyolefin shrink films are fully recyclable. In addition, our Ecolene® film is a biodegradable food packaging film that decomposes naturally under regular disposal conditions. Ecolene® employs groundbreaking technology to offer compostable food packaging without compromising on performance or appearance. Start your brand’s journey towards more sustainable food packaging today.

Food Packaging FAQs

What is the difference between food plastic wrap and food packaging film?

These two products may sound similar, but they usually refer to two different grades of film. Food plastic wrap generally refers to post-consumer use storage wrap. Familiar household kitchen products like saran wrap and food storage wrap fall into this category. Food plastic wrap is usually made out of a lower quality Polyethylene plastic with lower gloss and clarity. Food packaging film refers to a higher-quality polyolefin film. With its higher gloss and clarity, it is the film of choice for packaging food products in a commercial setting.

What are the advantages of using plastic food packaging?

Plastic food packaging offers numerous advantages, including its lightweight nature, durability, and versatility. It provides excellent protection against external elements, such as moisture and contaminants, while also extending the shelf life of food products. Additionally, plastic food packaging is often cost-effective and can be easily customized to meet specific packaging needs.

Is plastic food packaging safe for storing and transporting food products?

Yes, plastic food packaging is designed and manufactured to meet stringent safety standards. When used appropriately and in compliance with food safety regulations, plastic packaging provides a secure and hygienic solution for storing and transporting food products. It helps prevent contamination and maintains the integrity of the packaged food items.

What types of plastic materials are commonly used for food packaging?

Common types of plastic materials used for food packaging include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polystyrene (PS). Each material has specific properties that make it suitable for different types of food products and packaging requirements. Polyolefin (POF) is the highest grade of plastic for shrink packaging. Its superior optical properties make it the preferred material for plastic overwrap and forming films with non-barrier requirements.

Are there eco-friendly options available for plastic food packaging?

Yes, advancements in technology have led to the development of eco-friendly alternatives in the realm of plastic food packaging. Biodegradable and compostable plastics, such as our Ecolene® compostable film as well as recycled content plastics, offer sustainable options for food packaging while still providing the necessary protective and functional characteristics.

What considerations should be taken into account when choosing plastic food packaging for specific food products?

When selecting plastic food packaging, factors such as the type of food product, required barrier properties, environmental considerations, and regulatory requirements should be carefully considered. Understanding the specific needs of the food product and its packaging requirements will help in choosing the most suitable plastic packaging solution.