Our fast-paced, international, commerce-saturated world presents suppliers with two problems. One is that more products are transported across the country and the world. Packaging can be bulky and a burden for retailers to dispose of. Two, suppliers and retailers have the avoidable expense of paying people to fill shelves. The eager adoption of shelf-ready packaging successfully provides a solution to both!

Shelf-ready packaging (SRP) offers many advantages, especially in today’s eco-conscious world. It provides compact, branded, and often sustainable wrapping, boxing, and packaging. Consumer items are placed neatly into the packages that retailers merely open and place on display. There is no need to carefully line up little boxes of spices or gently balance piles of beauty products.

What is Shelf Ready Packaging?

Shelf ready packaging, also known as display-ready and retail-ready packaging, is a way of packaging ready-to-sell items that pre-organizes products for display and aids in restocking.

Display ready packaging incorporates branding logos, colors, and messaging on the outside and inside of the packaging.

Suppliers see that shelf-ready packaging enables manufacturers to package products more efficiently, retailers to fill shelves more quickly, and consumers to shop more easily.

Some Types of Retail Ready Packaging (RRP) Solutions

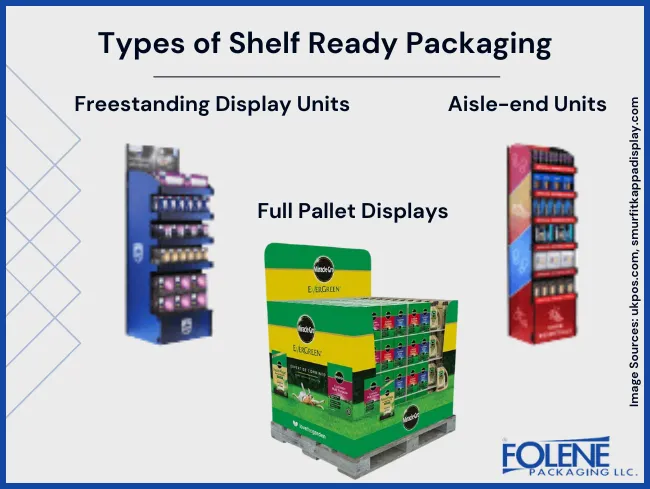

What is retail ready packaging? Some examples:

Prepacked shelf trays

Reusable plastic trays

Stand-alone retailing units

End-of-aisle units

Shrinkwrapping supports shelf-ready packaging and is useful for:

externally wrapping shelf trays made of corrugated cardboard

unitizing products

bundling multipacks

adding free gifts that encourage customers to try new products.

Market Trends in Shelf Ready Packaging

Shelf-ready packaging in boxes or bundles has been hugely successful since Walmart initiated the concept over 10 years ago. Data Insights Hub says that major manufacturers of shelf-ready packaging worldwide are now seeing steady growth, with North America and Europe in the lead.

In 2021, the retail ready packaging market stood at $62.9 billion USD. Steady growth is projected at the rate of 4.8% CAGR from 2022 to 2028, says GMI Insights. Worldwide, growth is improving how prepackaged fresh food and other food & beverages are produced and distributed.

A Freedonia analysis supported retail ready packaging market trends research by predicting that retail-ready packaging would grow quickest in the fresh produce sector: fresh vegetable and salad packages are valued at $3.5 billion.

Retail ready packaging examples

The top sectors in display-ready packaging expect growth between 2021 – 2024, increasing at the annual rate of:

Retail ready tomatoes: 5%

Pre-packaged salads: 5.5%

Retail ready boxes of potatoes: 5.4%

(N.V. Business Publications)

10 Benefits of Shelf Ready Packaging for Suppliers

1. Shelf-Ready Packaging Nurtures the Environment

Manufacturers can reduce environmental damage and connect to environmentally conscious consumers with shelf-ready packaging by prioritizing sustainability goals. Shelf ready display packaging can be easier to dispose of or recycle. Why? Polyolefin and PVC are the most common shrink-wrap materials used in shelf-ready packaging, with Polyolefin considered eco-friendly because it can be recycled. Additionally, stores collect the cardboard and shrink wrap from the packaging for recycling directly.

2. Shelf Ready Packaging Delivers Affordability For Manufacturers

Products are placed directly into retail-ready holders. Manufacturers reduce packaging costs by avoiding manual or automated transfer of the product from a conveyor belt or packing area to fill cases.

Once Manufacturers develop an effective shelf ready packaging design, they can maintain the external packaging design for the sake of brand awareness and consistency.

3. Shelf Ready Packaging Helps Retailers Economize

Shelf-ready packaging reduces labor costs associated with restocking shelves in bulk. With SRP, entire cases are restocked in one go. It is also quicker and easier for retail employees to display the product. Shopping clubs and pile-it-high purchasing centers can literally pile up retail-ready packages (also known as prêt-à-vendre, or PAV, packaging) ready for purchase.

4. SRP Satisfies Requirements of Diverse Sectors

Shelf ready packaging can satisfy grab-and-go shopping, sterile medical needs, and economy- and family-style shopping. The many sectors that use RRP packaging ideas include:

Food – fresh product packaging, ready-to-eat, or preserved foods

Beverages – twin packs of hard drinks, 4-packs of soft drinks, multipacks of kid’s juices

Confectionery – display boxes for gift chocolates, multipacks of chocolate bars

Beauty – suppliers take advantage of glossy or printed packaging for branding

Electronics – perfect protection at minimal expense

Over-the-counter drugs – safety and tamper evidence

Pile-and-sell or hang-and-sell items – think gardening centers, DIY centers.

5. Shelf-Ready Packaging Improves Space Utilization

The savings in packaging materials translate into suppliers and retail stores optimizing shelf space and displaying more shelf ready packaging boxes in less space.

6. Shelf ready packaging encourages purchases

People buy more, more easily.

A shelf ready package enhances product visibility.

The glossy shrink wrapping or printed cardboard packaging encourages customers to grab and drop products into their baskets.

Well-designed or eco-concious packaging boosts shooper loyalty.

SRP increases sales through unitization. Often, multi-pack bundling means people will buy one unit, comprising of more than one packet.

7. Ready for Retail Packaging is More Sanitary

SRP packaging is orderly and tidy from production and packaging until customers put them in their carts or receive a delivery. Less human touch of stock is more sanitary. Wrapping items settles the end-buyers’ worries as they see the product is tamper-proof.

8. SRP Packaging Increases Efficiency by Streamlining Logistics

Streamlined packaging designs create an economy in the transportation of the packaging—more can be fit into each delivery. Additionally, merchandise is shipped in packaging that ultimately stands on the sales floor, saving unpackaging and shelving. These time savings accelerate the entire supply chain. Going forward, products will be restocked in bulk – more quickly and with fewer empty shelves during the restocking stages.

9. Shelf Ready Packaging Reduces Waste Disposal Costs

Retail-ready packaging reduces time and money sorting waste, by easy-to-identy uniform types of waste. With experience, suppliers optimize packaging size and design. Economical-sized packaging, like heat-sensitive shrink films reduce waste end-mass, especially when using recyclable and biodegrable packaging.

10. Shelf Ready Packaging Has Built-In Marketing

Producers choose how they want to market and display the product by including all the marketing information on the retail ready package, exactly how they way want the customer to see it. Whether it is a beauty product, a ready-to-eat product, or a DIY item, all the branding is incorporated in the packaging of the sale unit and in the box or stand that comes with it. You choose what you want to highlight.

Retail Ready Packaging Makes It Easy

Walmart created the concept of “The Five Easies” for retail-ready packaging.

Easy to identify – by store staff for restocking. Yes, that is linked to branding.

Easy to open – by employees when preparing to fill the shelves.

Easy to replenish or stock – by the workers, who simply replace the tray.

Easy to shop – by customers to locate, identify what is 1 unit, and select.

Easy to dispose of and recycle – the merchandising unit is easily opened, dismantled, separated, and, if needed, folded until reuse.

New packaging ideas satisfy these requirements and avoid secondary packaging by using an efficient display box. The entire process can increase sales; its worth using creative services to reduce packaging costs, transport costs and achieve a better customer perception.

How Flxtite® Shrink Wrap Offers Manufacturers and Distributors an Amazing Advantage for Shelf Ready Packaging

Flxtite® Shrink Wrap film has an outstanding molecular structure that allows it to shrink evenly and tightly around products upon heat application. The wide range of Flxtite® films includes grades that are a perfect fit for different packaging applications.

For shrink wrap with super-high clarity and high gloss, Flxtite® offers AP-1. It is ideal for shelf ready display packaging, such as for chocolate and candy gift boxes, toys, electronics, and retail-ready food multipacks.

Chilled foods and fresh produce look better with the AP-XF shrink film available from Flxtite®. Its anti-fog formula enhances clarity and gloss and offers long-term resistance to liquid leakage. This feature also helps products retain freshness and cleanliness. AP-XF is your choice for shrink-wrapping produce, many types of meat, and other refrigerated items.

Contact Folene Packaging to learn more about how Flxtite® Shrink Wrap film can help you switch your products to shelf-ready packaging.