With the fascinating number of new plastic materials created through the application of science and physics, the types of plastic we can use encompass a wide range. Confusion exists as to how materials are sourced. With increasing awareness of sustainability topics, we attempt to balance how we use new (virgin) plastic materials with old (recycled) plastic materials.

Polyolefins aren’t that new, but the way they are being used today is. As awareness of health problems associated with other plastics emerges, we now use polyolefins to a greater extent in food products. As we try to find cost-efficient transport solutions, polyolefins provide an answer in the form of space-saving pallet wrap, among its many other uses. Learning more about how polyolefins are made and their properties can help manufacturers be informed and make better decisions about production, packaging, and end-of-use disposal.

What are Polyolefins?

Polyolefins are a versatile and popular type of plastic with a wide range of applications. Independent groups in the United States and Europe invented them in the 1930s, but they became commercially valuable in the 1950s. Due to the unique properties of olefins and polyolefins, this plastic was initially helpful in insulating underwater cables.

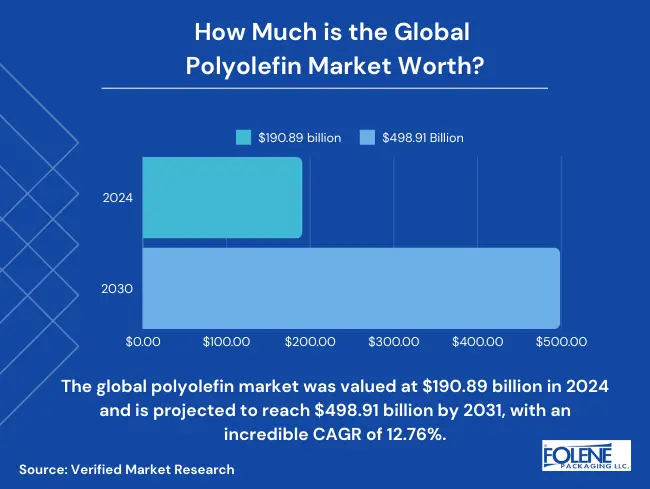

Polyolefins, produced from polyolefin resin, are part of a “family” of thermoplastics, including polyethylene and polypropylene. Polyolefins represent almost 70% of U.S. and European plastics consumption, making them one of the most widely used plastics. Verified Market Research reports the global polyolefin market was valued at $190.89 billion in 2024 and is projected to reach $498.91 billion by 2031, with an incredible CAGR of 12.76%.

Manufacturing Polyolefins

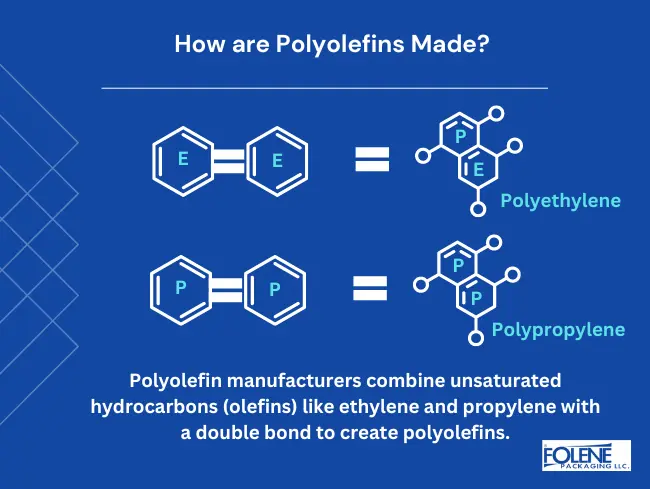

If you want to define “polyolefin,” it’s a polymer of an alkene. Let’s understand that polyolefin definition better.

Polyolefins are formed by combining raw materials with a double bond to create “polymers” (polymerizing). The raw materials are unsaturated hydrocarbons known as “olefins” ( which means “oil-like” or “alkenes”), such as ethylene and propylene.

What is polyolefin resin? Polyolefin (sometimes spelled polyolefine with an e at the end) is a “synthetic resin,” which is the term for the chemical compound primarily comprised of atoms, including carbon and hydrogen. Synthetic resin is a significant component of plastic.

What is polyolefin made of? The raw materials are sourced mainly from crude oil or natural gas, although renewable resources such as sugar cane derivatives containing carbon atoms are entering the market.

Polyolefins are produced through a variety of industrial processes, including naphtha cracking of crude oil and polymerization. The choice of process depends on cost, feedstock availability, and the additives and catalysts to be used. Some additional ingredients used are the Ziegler-Natta catalyst for better polymer synthesis or Chlorinated polyolefins, which are adhesion promoters.

The ready-to-use material is made into functional items through manufacturing methods that include extrusion, injection molding, blow molding, and rotational molding.

The properties of polyolefins formed are determined by their molecular weight and degree of crystallinity.

Polyolefins can be combined with other polymers to improve them.

6 Properties of Polyolefins Make Them a Top Choice for Manufacturers

1. Indefinite Use of Polyolefin Thermoplastic (Highly Recyclable)

Polyolefins are a type of thermoplastic. Thermoplastics can be melted and cast, which means that they can become molten and shaped. After use, they can be cleaned and reused or recast—or, in today’s vernacular, recycled – again and again.

2. Affordability of Polyolefin Raw Material

Thankfully, the raw materials for polyolefins are relatively inexpensive and widely available worldwide. For example, P.P. is the most affordable plastic for injection molding. This is due to the low cost of raw materials, ease of production, versatility, and potential for being recycled. Polyolefins are less costly than polyurethane, but some parties highlight the environmental costs of plastic waste.

3. Polyolefin Durability

Polyolefins are known for their high strength, durability, and resistance to chemicals and U.V. radiation. The durability of polyolefin fabric means it can be used indoors and outdoors and is adaptable in production through the addition of catalysts, stabilizers, and processes such as cross-linking. The result is a material that withstands degradation from natural environmental conditions (U.V. light, dampness, oxygen, and heat) for items with a longer useful life.

4. It’s Worth it to Make Polyolefin Materials and Fabrics

We can make fabrics and soft materials from polymerized ethylene or propylene. Polyolefin fabrics are lightweight, quick-drying, strong, and tough. What is polyolefin fiber? These are fibers that are stain-resistant and protected against moisture and mildew. For example, polyolefin canvas is made using extrusion technology for the fabric itself and then P.P. laminated.

5. Versatility in Polyolefin Uses

Polyolefins can be used to make both flexible and rigid types of plastic. This adaptability and versatility means that the same material can be used for many different uses. See the exhaustive list below.

6. Stable Polyolefin Melting Temperatures

In production, polyolefin polymers function well across a wide temperature range. After production, they also retain their predictable temperature resiliency across a wide range. This is reflected in the broad range of uses polyolefins are suitable for. Polyolefin plastic items are often marketed with notations that the plastics can withstand higher temperatures. The polyolefin heat shrink temperature is very relevant for manufacturers, suppliers, and distributors. Heat guns or other equipment can be used to apply heat for shrink packaging at low temperatures.

12 Uses of Polyolefins – An Impressive List

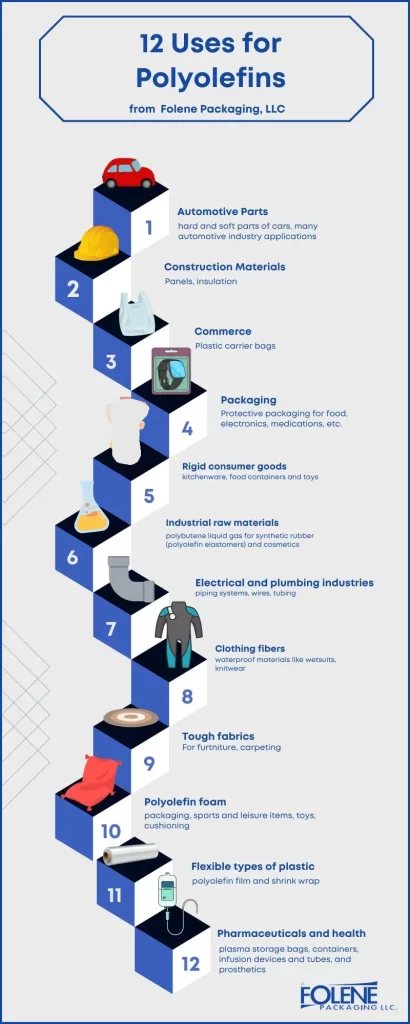

What is polyolefin plastic used for? The booming growth rate in the polyolefin market is not surprising, considering the range of polyolefin applications and its stable physical properties.

The specific qualities of different grades and gauges of each type of polyolefins allow for diversity in items commonly produced. Here are just some of the many uses for polyolefins:

Automotive parts – e.g., hard and soft parts of cars and many uses in the automotive industry

Construction materials – e.g., structural panels, insulation

Commerce – plastic carrier bags

Packaging – e.g., for food and electronics

Rigid consumer goods – e.g., kitchenware, food containers and toys

Industrial raw materials – e.g., polybutene liquid gas for synthetic rubber (polyolefin elastomers) and cosmetics.

Electrical and plumbing industry – piping systems, wires, tubing

Clothing fibers – waterproof items, e.g., wetsuits, and other clothing items, e.g., knitwear

Tough fabrics – e.g., for furniture and carpets

Polyolefin foam – used, e.g., packaging, sports and leisure items, toys, cushioning

Flexible types of plastic, e.g., polyolefin film and shrink wrap, which are marketed on a roll

Pharmaceuticals and health – e.g., plasma storage bags, containers, infusion devices and tubes, and prosthetics

Polyolefins: Common Types of Polymers

Since polymers are combined types of chemicals, the names of polymer chains are pretty long. For the sake of convenience, we refer to them by their abbreviated names. Here are the main types of polyolefins and their initial letters.

Three types of Polyethylene (P.E.)

Low-density polyethylene (LDPE)

Linear low-density polyethylene (LLDPE)

High-density polyethylene (HDPE)

One type of polypropylene

Polypropylene (P.P.)

One type of synthetic rubber

Ethylene propylene diene monomer (EPDM)

The most common types of polyolefins are P.P. and P.E.

Michigan State University offers a comprehensive table that explains polymers, their chemical formulas, and their scientific properties.

What is “Polyolefin Density”?

Polyolefins demonstrate different properties based on the density of the material produced. Density is measured in g/cm3, grams in a cubic centimeter. For example, HDPE has a density of between 0.93 and 0.97 g/cm3, and it can withstand temperatures of up to 120 degrees centigrade. P.P., however, has a density of between 0.895 and 0.92 g/cm³, and its mechanical properties and thermal resistance are strong, but its chemical resistance is less strong.

Sheets of polyolefins are marketed in different strengths and gauges, yielding a range of polyolefin products suitable for a range of applications. Folene packaging offers a full range of shrink films and wraps. Each type of film has different properties, so it is important to get the advice of a professional when choosing your products.

Reprocessing Polyolefins

Polyolefin is often used to make shrink films. What is polyolefin shrink film? It is the transparent, glossy plastic used to wrap fresh produce in the supermarket and the taut material used to bind twin packs together.

Environmentally conscious users and manufacturers want to know: Is polyolefin shrink film recyclable? The answer is yes; most, if not all, types of polyolefins can be reprocessed. However, since polymers can be complex to purify after use, textiles, kitchenware, and lab equipment are often made from virgin material, while construction materials might be made from recycled material. So, different types of polyolefins are used in various applications.

Environmental remediation for polyolefins, until they are more degradable, includes sifting municipal trash, collecting polyethylene bags, and filtering the oceans. So, it’s good that researchers at the University of Texas are developing a plastic-eating enzyme to address the problem of plastic waste.

How Folene Packaging’s Range of Polyolefin Products Leads The Way

Folene Packaging produces a full range of polyolefin films that are excellent packing resources for manufacturers, suppliers, and distributors. The films are printable and can be ordered with or without perforations. They come in various gauges and widths. Folene Packaging offers the Flxtite® range, including super high clarity, extra glossy Flxtite® AP-1, and Ecolene® 100% biodegradable shrink film.

Folene Packaging offers a smooth-running production system. We have vast stocks of prepared European-grade starting material, which we turn into “packaging gold” speedily in the USA. This allows us to deliver within days, not weeks. With our raw feedstock supply based in Europe and the final product produced in the USA, our customers get the best advantages of speed and lower delivery costs.

Contact Folene Packaging to learn how our polyolefins in the form of shrink films could help you produce, distribute, and retail your products more efficiently.

FAQs about Polyolefins

What is a polyolefin coating?

Polyolefin coating is a protective coating applied to the surface of a product or component. Polyolefin coating is a surface treatment often used for added crack resistance. Common coating applications are specialized flooring, kitchen countertops, sticky labels, and items needing prolonged U.V. or saltwater protection without yellowing or corroding, such as outdoor furniture, railings, and playground equipment.

What is polyolefin fabric?

A polyolefin fabric is one whose fiber-forming substance is polyolefin. Examples of polyolefin fabrics are Herculon, Marvess, and Vectra (these are their common trade names). furnishings and industrial fabrics. What is polyolefin material used for? TextileSchool lists fabric uses, including carpeting, carpet backing, upholstery, seat coverings, chair webbing, nonwoven fabrics, laundry bags, adults and children’s hosiery, and blended fiber knitwear, fishing nets – mainly due to its water and mildew resistance – ropes, filters, and other industrial fabrics.

How tough is polyolefin plastic?

Polyolefin plastics can withstand temperatures of up to 120 degrees centigrade. They can also withstand chemical, seawater, and U.V. light corrosion. Polyolefin offers exceptional tensile strength and is puncture-resistant after a certain thickness and tear-resistant. Its puncture resistance makes it an excellent choice for tamper-resistant bands. Its weather resistance protects wares until they reach the warehouse, in long sea transits, and from jostling while on the road. Marine-grade polyolefins are great for protecting boats; they are strong enough for building and roofing.