With the ever-expanding rise of e-commerce, many smaller-to-mid-sized manufacturers and distributors are beginning to look towards packaging automation to increase operations efficiency and fill more orders quickly and accurately. Folene Packaging discusses different automated packaging systems, how to find the right one for your operations, and how to select the right packaging materials.

What is Automated Packaging?

Automated packaging uses technology and machinery to automate different stages of the packaging process, enhancing efficiency, accuracy, and consistency. These systems can be tailored to handle a variety of products, from small consumer items to large industrial components. The most significant advantage of automation is the ability to place simple, yet crucial, repetitive tasks on repeat and increase the speed. The reality is that automated packaging machinery significantly speeds up operations and means that products are packaged faster, more efficiently, and with less error than relying primarily on manual labor. Nevertheless, human touch and oversight remain essential, particularly when it comes to quality assurance.

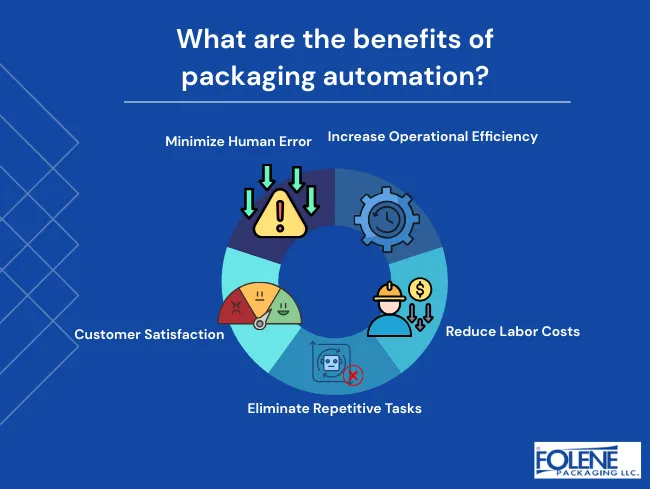

Benefits of Automation

There are several key benefits of shifting towards automation in packaging processes. Here are a few:

Improve operational efficiency by automating repetitive tasks and reducing manual processes.

Reduce labor costs by eliminating the need for human labor in repetitive tasks and improve workflow. This is particularly important in light of recent labor shortages; the ability to maintain productivity without relying on manual labor is integral to business success.

Enhance customer satisfaction by providing faster and more accurate delivery of products.

Minimize human error and improve quality control with automated packaging.

These substantial benefits make a strong case for manufacturers and growing e-commerce entrepreneurs to incorporate automation into some if not all, aspects of their operations.

How Automated Packaging Works

Automated packaging utilizes technology to blend precision and speed at several stages of the packaging process. You can incorporate automation at multiple points in the packing process: product reception and identification, sorting and orientation, selection of packaging materials, packing and cushioning, sealing and labeling, quality check and verification, and sorting and dispatch.

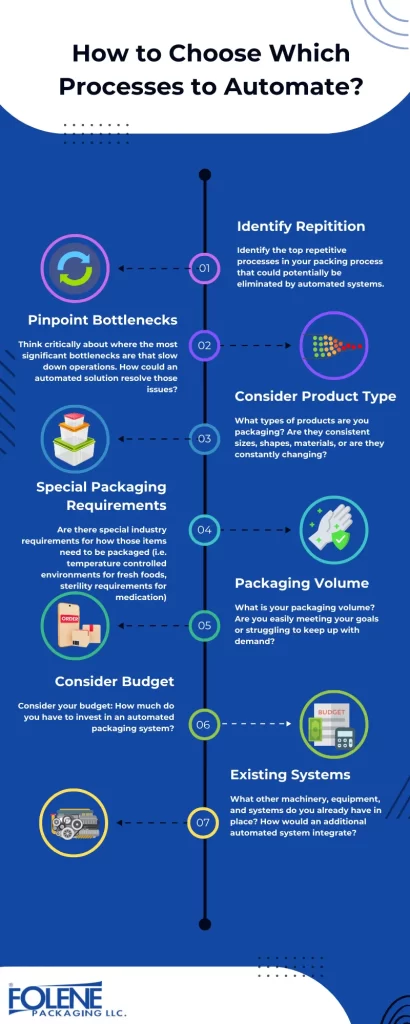

How to Choose Which Processes to Automate

What steps you will choose to automate in your operations will depend on a few factors:

Identify the top repetitive processes in your packing process that could potentially be eliminated by automated systems.

Think critically about where the most significant bottlenecks are that slow down operations. How could an automated solution resolve those issues?

What types of products are you packaging? Are they consistent sizes, shapes, materials, or are they constantly changing?

Are there special industry requirements for how those items need to be packaged (i.e. temperature controlled environments for fresh foods, sterility requirements for medications or medical devices)

What is your packaging volume? Are you easily meeting your goals or struggling to keep up with demand?

Consider your budget: How much do you have to invest in an automated packaging system?

Once you have pinpointed the step or steps that would benefit most from automation, you’ll need to find automated packaging equipment to implement automation into that step of operations. Packaging machinery includes various machines structured for specific purposes, such as bagging systems, packaging equipment, sorting, orienting, and labeling machines. Automated sensors measure specific characteristics of objects or systems throughout the packaging process, ensuring a seamless flow of production from one process to the next and improving efficiency, quality, and safety.

Choosing the Right Level of Automation

Some manufacturers may find it better to automate only specific tasks, at least initially, especially if operating on a limited budget. The benefit of semi-automated systems is that they can reduce the risk of machinery breakdowns disrupting operations. In contrast, fully automated packaging systems require contingency plans in case of breakdowns or incidents. However, fully automated systems can crank up efficiency much more than semi-automated machinery, which may be more beneficial to manufacturers with multiple repetitive tasks. Ultimately, you will have to decide which system makes the most sense for your operations.

Integration with Other Systems

Automated packaging systems can usually be integrated with existing warehouse management systems quite easily to automatically monitor packaging processes. This can further assist with accurate inventory management, improving order fulfillment and customer satisfaction. Integration is generally seamless, allowing teams to focus on other tasks. Automated packaging systems can be customized to meet specific packaging needs and goals.

ROI of Packaging Process Optimization

The costs of investing in packaging automation can seem daunting. It’s important to remember that it is more than machinery; it’s an investment in optimizing your overall packaging process. Packaging automation systems increase productivity and reduce inefficiencies so that many companies can achieve a return on investment (ROI) in under a year. Investments in automated packaging machines should be weighed against the benefits they bring.

Packaging Process Optimization: Creating Intelligent Systems with IoT

IoT technology can help with logistics operations, optimize inventory control, and improve customer service. Automation combined with IoT technology can reduce waste and defects in packaging. Manufacturers can leverage IoT to identify problems and understand inefficiencies in current packaging processes, then suggest future enhancements for more streamlined outcomes. IoT technology can track products through the packaging stage and beyond.

Selecting the Right Packaging Materials for your Automated Packaging System

Folene packaging offers a wide range of premium quality shrink films that are compatible with most semi-automatic and fully automated packaging systems. Our range of films includes heavy-duty film for sharp or heavy objects, specially formulated biodegradable film for eco-conscious brands, retail display films for consumer items, and anti-fog films for refrigerated and frozen food items. Most films perform well in high-speed packaging environments, increasing production efficiency and allowing companies to shift towards fit-to-size packaging, resulting in a smaller environmental footprint. Ready to switch over to Folene Packaging’s Flxtite and Ecolene films for automated packaging systems? Reach out to determine the best film for your products.

The Packaging Automation Revolution: In Conclusion

Automated packaging systems are revolutionizing the packaging industry by improving efficiency, reducing costs, and enhancing customer satisfaction. By understanding the benefits and components of automated packaging, businesses can make informed decisions about implementing these systems. With the right level of automation, businesses can significantly improve their packaging operations and stay competitive in the market.