What is Modified Atmosphere Packaging?

Modified atmosphere packaging (MAP) is a packaging process that modifies the internal atmosphere of a package to improve its shelf life and achieve shelf life extension. This innovative technology actively or passively controls the atmosphere surrounding the product using a combination of specific packaging materials and gas replacement processes to achieve the ideal packaging atmosphere and seal. The goal of MAP food packaging is to increase the product’s shelf life by reducing oxidation and spoilage of perishable foods and beverages by manipulating the packaging atmosphere rather than the food itself.

How Does Modified Atmosphere Packaging Work?

Under regular packaging conditions, perishable foods are exposed to some level of oxygen and react by producing lipid oxidation. This creates high respiration rates in fruits and vegetables, meaning they lose their internal moisture much more quickly, leading to shortened shelf life. High respiration rates are responsible for short shelf lives, discoloration, and taste deterioration. In addition, high levels of oxygen allow the growth of spoilage organisms like mold, rendering the food unsafe for consumption.

2 Types of Modified Atmosphere Packaging

Modified atmosphere packaging (MAP) can be broadly categorized into two main types: active and passive. Each type employs different methods to create an optimal environment within the packaging, thereby extending the shelf life of food products.

The MAP process lowers the volume of oxygen inside of the packaging to reduce this reaction and slow the respiration and decomposition processes either passively or actively.

Passive Modified Atmosphere Packaging

Passive MAP packaging focuses on using specific packaging materials to achieve the desired atmosphere. The ideal atmosphere naturally occurs through the respiration process of the packaged food and the properties of the packaging film. Generally, barrier films are used for passive MAP food packaging to prevent over-oxidation.

Active Modified Atmosphere Packaging

In active MAP applications, the food packager replaces all or most of the oxygen inside the package with other gases, such as carbon dioxide or nitrogen, to lengthen the product’s shelf life. For fresh fruits and vegetables, the ideal oxygen level is around 3-5% to slow the respiration rate and reduce perishability. In some instances, this method is combined with various passive MAP packaging techniques, like vacuum packing, to extend the perishable product’s expiration date further.

However, not all food items are well-suited to vacuum packaging, and rely on the package volume for cushioning to prevent damage to the product (usually the case with dry or brittle items like crackers and snack packages) In those cases, replacing the oxygen in the package with inert gasses like nitrogen has the added benefit of preventing package collapse. The nitrogen can maintain the internal packaging volume while simultaneously extending the product’s shelf life.

Alternatively to gas flushing, packagers also use other methods to actively modify the packaging atmosphere, such as one-way valves to release CO2 gases (used for coffee beans) and oxygen scavenger or desiccant packs (often used in pharmaceutical packaging) to actively remove excess oxygen and moisture from the package.

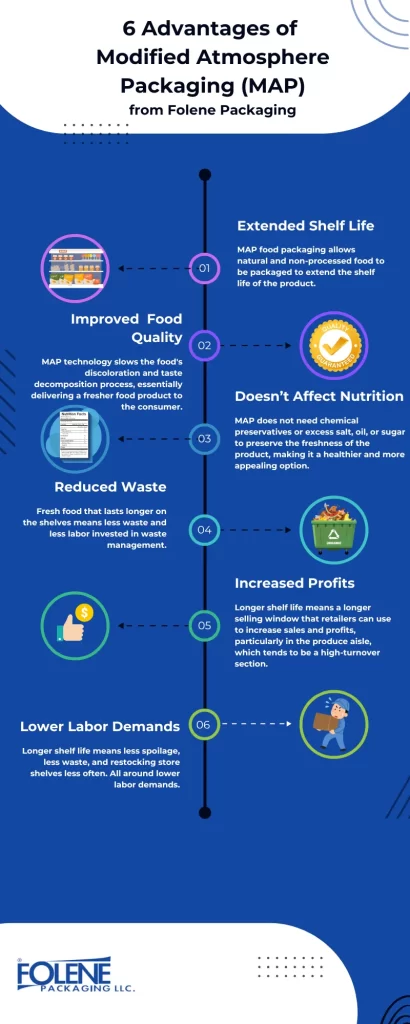

Benefits of Modified Atmosphere Packaging

There are several significant benefits to using MAP in food packaging processes. Here we explore some of the main benefits for consumers, manufacturers, wholesalers, and retailers.

Extended Shelf Life

MAP food packaging allows natural and non-processed food to be packaged to extend the shelf life of the product. This makes a huge difference in profitability for food wholesalers and retailers, as a longer shelf life means a larger window of time in which the food can be sold, resulting in less waste and turnover.

Improved Food Quality

MAP technology slows the food’s discoloration and taste decomposition process, essentially delivering a fresher food product to the consumer.

Does not affect the food’s nutrition

MAP does not need chemical preservatives or excess salt, oil, or sugar to preserve the freshness of the product, making it a healthier and more appealing option.

Reduced waste

Fresh food that lasts longer on the shelves means less waste and less labor invested in waste management.

Increased profits

Longer shelf life means a longer selling window that retailers can use to increase sales and profits, particularly in the produce aisle, which tends to be a high-turnover section.

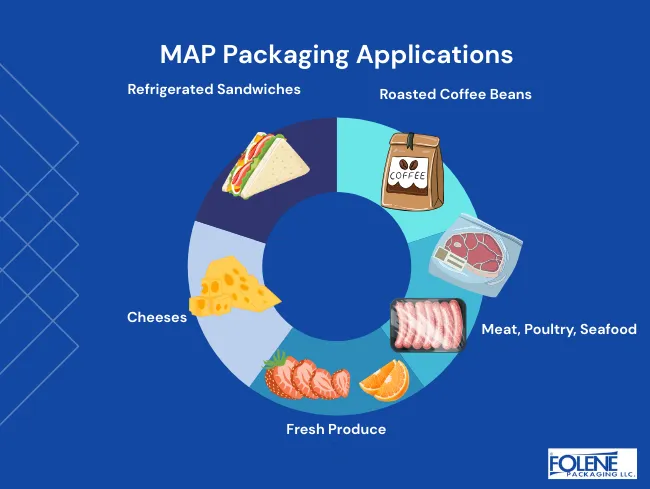

Applications of Modified Atmosphere Packaging

Fresh-cut fruits and vegetables often combine active and passive modified atmosphere packaging, including nitrogen gas flush and specific barrier packaging films.

Snack producers use barrier packaging films to protect the freshness of their products and extend shelf life.

Coffee beans release carbon dioxide after roasting, which can cause the package to burst if not controlled. Coffee bean packagers often utilize a one-way valve to control the package atmosphere and release the carbon dioxide from the coffee bag without letting in any ambient environmental gases.

Types of Packaging Materials Used in MAP

Flexible films are commonly used for products such as fresh produce, meats, fish, and bread, providing suitable permeability for gases and water vapor to reach the desired atmosphere.

Pre-formed trays are formed and sent to the food packaging facility, where they are filled, while thermoformed packaging materials are received in the food packaging facility as a roll of sheets.

Various packaging films, including Polyethylene (PE), Polyamide (PA), Polyethylene terephthalate (PET), Polypropylene (PP), Expanded polystyrene (EPS), Polyvinyl chloride (PVC), and Polyvinylidene chloride (PVDC) are used in MAP packaging.

Modified Atmosphere Packaging Machines and Equipment

There are 3 main types of machines used in MAP: thermoforming, vacuum skin packaging, and form fill seal machines.

Thermoforming MAP packaging machines are fed with a rigid plastic sheet to form package trays and a flexible plastic sheet to seal them.

Vacuum skin packaging machines remove the air from the package and seal it.

Form fill seal machines form and cut a pouch from a plastic film, fill it, and seal it all in one system.

Monitoring and Safety in Modified Atmosphere Packaging

Although MAP technology has significant benefits for improving perishable food’s quality, safety, shelf life, and storage capacity, it is not foolproof. The FDA cautions that MAP packaged foods can still harbor and develop food borne illnesses such as salmonella. As such, MAP packaging processes require extra vigilance for food safety and quality control. Let’s examine some of the details that need monitoring in modified atmosphere packaging:

Gas analyzers

package leak detectors

temperature control checks

headspace analyzers

Investing in the proper equipment and developing and following strict MAP production procedures can increase product safety, quality control, and ensure the best food packaging outcomes for both producers and consumers.

Safety and Regulatory Considerations

While modified atmosphere packaging (MAP) offers numerous benefits in extending the shelf life and maintaining the quality of food products, it also comes with important safety and regulatory considerations. The use of gases such as carbon dioxide and nitrogen must be carefully managed to ensure consumer safety.

Opportunities and Future of Food Packaging

Modified atmosphere packaged (MAP) products can be found in almost every aisle of the supermarket today. This advanced technology allows food packagers to extend the shelf life quality of otherwise highly perishable foods, reducing food waste and increasing food safety and profitability across the supply chain. MAP is a principal technology utilized in food categories such as fresh-cut produce, specialty cheeses, meat, fish, poultry, seafood, and refrigerated sandwiches. The fresh-cut produce category is projected to evolve considerably in the years ahead due to continual advances and applications of packaging technology.

MAP food packaging has many benefits to offer food packagers and consumers. When applied correctly, MAP packaging principles can reduce food waste and promote a healthier and more sustainable circular economy for us all.

Conclusion

Modified atmosphere packaging (MAP) is a transformative technology in the food industry, offering significant benefits in extending the shelf life and maintaining the quality of perishable products. By understanding the different types of MAP—active and passive—manufacturers can choose the most suitable method for their specific needs. Active MAP uses gases like carbon dioxide and nitrogen to create an optimal environment, while passive MAP relies on the natural respiration of the product and the properties of the packaging material.

However, it is crucial to consider the safety and regulatory aspects associated with MAP. Proper handling of gases, prevention of microbial growth, and adherence to regulatory guidelines are essential to ensure the safety and quality of MAP-packaged food products.

In conclusion, modified atmosphere packaging is a powerful tool that, when used correctly, can significantly reduce food spoilage, extend shelf life, and improve the overall quality of food products. By staying informed about the latest advancements and maintaining rigorous safety standards, food manufacturers can leverage MAP technology to deliver fresher, safer, and more sustainable products to consumers.