With increasing raw material expenses and frequent international product shortages, suppliers are trying to cut back on expenses. One effective way is to reduce shipping costs. Learn how to decrease shipping costs and downgauge packaging to save money and increase your profit margin.

Solutions to high shipping costs begin with suppliers investigating how lightweight packing materials can lower shipping costs. Smaller players are not the only ones researching how to reduce shipping costs for small businesses. Bigger businesses and major e-commerce businesses are also desperate to save on shipping costs.

Why And How To Reduce Shipping Costs

CNBC’s shipping data reports one reason for this may be that 80% of consumers seek mid-range price items, and 69% of consumers are clearly looking for discounts. Suppliers that know how to reduce shipping costs don’t need to inflate their prices as much to account for shipping and pass those savings onto consumers, providing value-driven shopping.

Folene Packaging shares packaging optimization advice on how to downgauge packaging. Focusing on sustainability and efficiency can help you achieve light and strong, minimal yet protective packaging. Your company can achieve a low shipping cost, and discover how lightweight packaging, such as flexible overwrap, can help achieve this goal.

How can we lower shipping costs, and why are they so high?

Shipping costs for an e-commerce business are the costs of mailing or delivering your product. Shipping costs for large businesses can mean delivering enormous orders with major carriers comprising many pallets or container loads. Understanding shipping costs is especially crucial for e-commerce businesses because it affects slim profit margins. All the more so, for large businesses, a small change in packaging and shipping costs can translate into thousands of dollars of savings.

Container freight rates rose steeply between January 2023 and March 2024. Statista reports that freight rates plummeted in response to the high prices, reaching a low in October 2023. A 40-ft shipping container cost $1,342 in October 2023. By June 2024, the price for the same container reached a record $5,800.

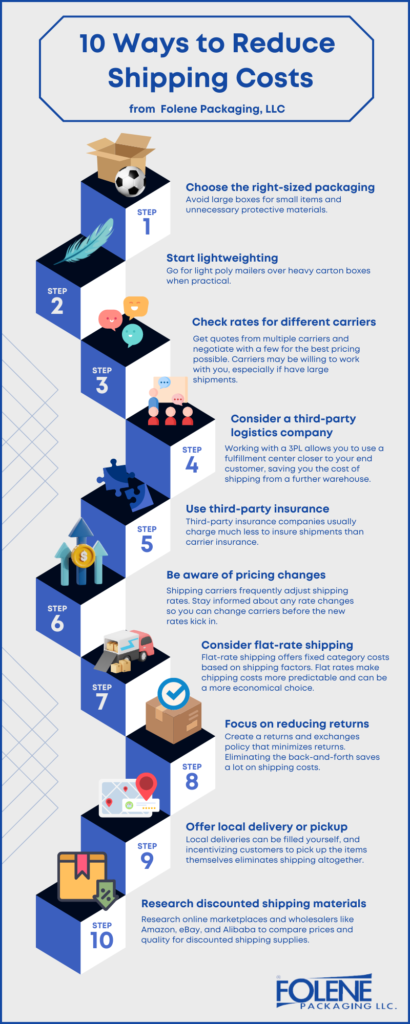

The top 15 ways to reduce shipping costs

Suppliers have responded to the shipping cost crisis by looking at ways to increase their shipping cost savings. Packaging optimization means investigating the cheapest way to ship, from discounted shipping rates to prepaid shipping labels. Here are some professional suggestions for packaging optimization:

1. Packaging optimization: Choose the right-sized packaging

- Use lighter packaging materials to save on weight-related costs and gas costs. Use minimal packaging sizes and weights to save a lot of money with lightweight shipping.

- Try using shrink wrapping to bundle goods conveniently, unitize deliveries, and avoid waste.

- Reduce package weight and dimensions to fit more items into each container/pallet/delivery.

2. Packaging lightweighting: Consider using poly mailers instead of boxes

- What is lightweighting? Lightweighting means removing weight from an item – a product or its packaging by combining different, lighter materials. Downgauging packaging helps you save on fuel and energy costs.

- Poly mailers, the ultimate in lightweight, convenient packaging, are cheaper than boxes.

- Use poly mailers for non-fragile goods like clothes that are light in weight.

- Pack different products with different-sized poly mailers or flexible overwrapping.

3. Lower your shipping cost: Investigate how much different carriers are charging

- Negotiate with multiple carriers and choose the best rate.

- Some shipping companies sell prepaid shipping labels at cheaper rates. Shop around for cheaper shipping labels.

- Choose carriers dedicated to eco-conscious practices while saving you money. 25% of consumers would choose a delivery option with a low carbon emissions statement.

4. Use third-party insurance to reduce shipping fees

- Third-party insurance companies usually charge much less to insure shipments than carrier insurance.

- If your product is low-value or if you team up with a 3PL (see next point below), consider eliminating shipping insurance altogether.

5. Reduce shipping costs by linking up with a fulfillment center

- Suppliers that team up with a third-party logistics (3PL) company use the external e-commerce warehouse located closest to the end users. Deliveries are made from the closest location to the customer. It’s convenient and saves time and the costs of delivering from a distance.

- Evaluate your options. Working with multiple distribution centers can save a lot on shipping costs, but it can be complex and require full digital inventory management.

6. Create a shipping policy: Clarify procedures and reduce shipping costs

- It is easier to manage your costs when you have a list of standard shipping rates. Being clear and consistent also puts customers at ease.

- Offer customers more than one shipping scenario and explain the advantages of each.

- Balance your shipping cost savings strategy while ensuring a pleasurable unboxing experience for your customer using thoughtful, fun, on-brand packaging. Take into account the psychology of online shopping and consumer preferences to understand where you cannot cut back.

7. Be aware of pricing changes: choose the carriers with lower shipping costs

- Shipping carriers frequently adjust shipping rates. Stay informed about any rate changes so you can make necessary adjustments before the new rates kick in.

- Keep track of every shipping-related expense, including shipping costs and additional shipping fees.

8. Discounted shipping labels from platforms and marketplaces mean lower costs

- Research online marketplaces and wholesalers like Amazon, eBay, and Alibaba to compare prices and quality who sell discounted shipping supplies.

- Consider partnering with major carriers that have multiple third-party fulfillment centers.

9. The shipping destination and its impact on shipping fees

- Know where is the location you are shipping to. The state legislature and shipping zones can affect your costs.

- Offer bulk shipping to specific destinations at a lower per-item fee; this usually entices consumers or retailers to buy more and lowers shipping costs.

10. Learn about reducing shipping fees so you can stay informed

- Compare air shipping versus sea shipping versus land shipping. Ground shipping is often the cheapest way, but the delivery takes longer.

- Some suppliers choose to include shipping fees in the final bill and state “free shipping,” which consumers find more acceptable.

11. Flat-rate shipping costs are economical

- Flat-rate shipping makes shipping costs more predictable, which helps suppliers and consumers.

- Flat-rate shipping offers fixed category costs based on shipping factors.

12. Offer local delivery or pickup to reduce shipping costs

- Local deliveries can be filled yourself. It’s the cheapest shipping method.

- Ask a local business if your customers can pick up purchases from an arranged place.

13. Focus on reducing returns to minimize shipping costs

- Have a returns and exchanges policy that minimizes returns. Replacing items saves shipping carrier costs and improves customer loyalty.

- Offer free shipping. This encourages up to 80% of customers to complete purchases and meet minimum purchasing thresholds.

14. Use profit tools to become aware of packaging costs

- Use a free online profit margin calculator to calculate your profit – and identify avoidable costs.

- Estimate the average shipping cost with a branded packaging cost calculator (or manually, from time to time, using the humble pencil and paper method) to really understand how much shipping affects your profit margin.

15. Let logic guide your business success to reduce shipping costs

- Don’t ship air! Other than eco-friendly air pillows, reduce shipping volume and bulky packaging. Save money with newer, snugger packaging options, lightweighting products, and lightweight packaging.

- Weigh products; don’t rely on estimates. One product may seem to be light in weight, but many items with extra weight add up to a lot of unnecessary shipping fees.

How Using Folene Packaging Flxtite® Films Can Help You Reduce Shipping Costs

Folene Packaging offers an impressive range of Flxtite® shrink films, one of today’s lightest and least bulky packaging materials. Our range of strong, protective overwraps is made of powerful polymer-based plastic. When Flxtite® shrink wraps are heated, they shrink around the product, simultaneously packaging, holding, and protecting the item. This is the ultimate development in lightweighting packaging—the same strong packaging, in a much lighter form.

Flxtite® shrink films offer the potential for considerable reductions in shipping costs as you consolidate your shipments. Enjoy unitized, printable-plastic-wrapped items and avoid bulky cardboard boxes that consume warehouse space and shipping weight. Remember, shrink wrap is lighter in weight than many other types of packaging and a lot cheaper, too. Bind pallets in the most space-economical way and fit much more into delivery units than you ever did before. Benefit from all this with guaranteed-strength, eco-friendly shrink wrap.

Contact Folene Packaging today to learn more about our customizable retail packaging shrink film and how to reduce shipping costs.