Heat Sealing Films: Defined

Heat sealable films are specialized multi-layered polyolefin films made to withstand higher levels of heat. They are used over more traditional shrink films to create a seal with extra strength and tear resistance. The higher sealing temperatures, along with the multiple layers of plastic, create an unusually strong closure that works well in several packaging applications, such as food and pharmaceutical packaging, that require a high level of protection.

The process involves applying heat to the plastic material, causing it to melt and fuse, forming a secure closure. This method is particularly prevalent in packaging food, pharmaceutical, and medical products because it creates strong, reliable seals. A heat seal is essential in these applications to ensure product integrity and preservation.

Of course, the heat-sealing method can be adapted to various forms of packaging materials, including heat-sealed pouches, bags, and containers. The heat sealing process, temperatures, speed, and other variables can also be adjusted to suit different product packaging needs. A heat sealer is crucial in this process, as it applies the necessary heat and pressure to achieve the desired seal strength. By controlling the heating process with a sealing bar, manufacturers can ensure that the seals withstand the required temperatures, maintaining the integrity and safety of the packaged products. In this article, Folene Packaging explores the particular benefits and applications of heat-sealable films.

Understanding Heat Sealing

Heat sealing is a fundamental process in the packaging industry, where heat is applied to bond two layers of plastic together. This method is particularly prevalent in packaging food, pharmaceutical, and medical products due to its ability to create strong, reliable seals. The process involves applying heat to the plastic material, causing it to melt and fuse, forming a secure closure.

The heat sealing process is highly versatile, allowing for adjustments in temperature, pressure, and sealing time to achieve the desired seal strength. This adaptability makes it suitable for various packaging applications, including flexible packaging, rigid packaging, and semi-rigid packaging. For instance, flexible packaging, such as pouches and bags, benefits from heat sealing by providing airtight seals that preserve product freshness and extend shelf life.

Moreover, heat sealing is essential for packaging products that require high heat resistance, such as ovenable and microwaveable items. By controlling the heating process, manufacturers can ensure that the seals withstand the required temperatures, maintaining the integrity and safety of the packaged products.

Benefits of Heat Sealable Films

Food preservation: Heat sealable films provide superior protection against moisture and oxygen, keeping products fresher longer. These films are particularly effective for packaging fresh produce, enhancing shelf life and appeal. Choosing these types of films is passive MAP food packaging, as these materials are particularly well-suited to maintaining food freshness for longer periods of time.

Flexibility: These films can be molded into various packaging types, such as stand-up pouches, flat bottom bags, and shrink sleeves, accommodating different product needs. Additionally, lidding films offer enhanced shelf appeal and superior sealing technologies for various food products, including meat, fish, and fresh produce.

Durability: Heat sealable films are designed to withstand handling and transportation, ensuring that packaged goods remain intact.

Ideal for Sensitive and Confidential Products: They are particularly suitable for packaging delicate items like food and pharmaceuticals, which require a high level of protection and preservation. Strong seals deter the wrong recipients from opening the packaging.

Reduction of Food Waste: By effectively sealing out air and moisture, heat sealable films help minimize spoilage, thus reducing food waste.

Tamper-Evident Solutions: These films can be designed to provide security features, ensuring that packaged products are tamper-proof and safe for consumers.

Applications of Heat Sealable Films

Heat sealable films find extensive use across multiple industries, thanks to their exceptional heat resistance and sealing properties. These films are particularly valuable in food packaging, pharmaceutical packaging, and medical packaging, where maintaining product integrity and safety is paramount.

In the food industry, heat sealable films are used for ovenable packaging, such as frozen meals and baked goods, ensuring that the packaging can withstand high cooking temperatures. Similarly, microwaveable packaging for products like popcorn and frozen vegetables relies on heat sealable films to provide secure seals that endure microwave heating.

Pharmaceutical packaging also benefits from heat sealable films, which are used to package pills, capsules, and other medicinal products. These films offer a high level of protection against moisture and contaminants, preserving the efficacy of the medications. In the medical field, heat sealable films are employed to package surgical instruments and medical devices, ensuring sterility and preventing contamination.

Overall, the versatility and reliability of heat-sealable films make them indispensable in applications where high heat resistance and strong seals are crucial.

6 Tips to Choose the Right Heat Sealable Film

When choosing a heat sealable film, it’s important to consider several factors about the specific needs of your product and application. Here are a few points to help put you in the right direction when making this important packaging decision.

The type of product you are packaging

Desired level of protection and preservation

Intended use of the package- is it a gift basket or retail shelf item where optics are important? Or is it meant to be more functional secondary packaging to preserve products during transportation? This will influence the optical properties of the film you’ll select.

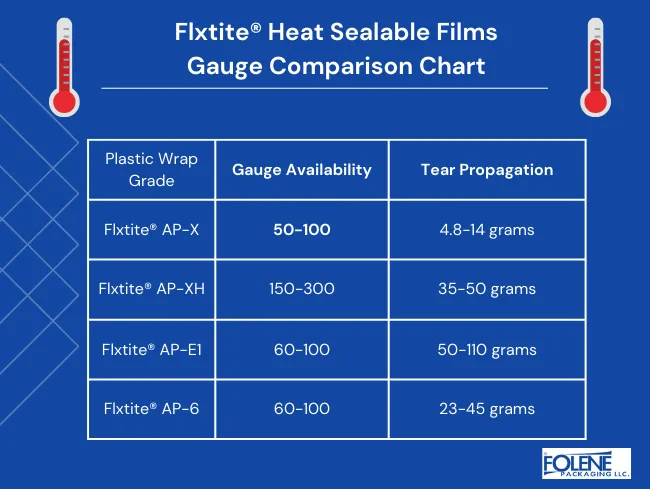

Product & Film dimensions Heat sealable films come in a variety of thicknesses, widths, and materials, so it’s important to choose a film that meets your specific needs. Additionally, each type of thermo-reactive plastic has a required temperature that must be met to ensure a proper seal.

Equipment Compatibility- Always check the compatibility of the film with your packaging equipment by ordering a sample roll and performing thorough packaging testing of the heat sealing process. For lower production levels and lighter materials, consider using impulse heat sealers, which operate using short bursts of heat.

Consult with a packaging expert or supplier to determine the best heat sealable film for your application.

Best Heat Sealable Films: Folene Packaging’s Top Picks

Folene packaging offers a wide range of high quality films for various packaging applications. Here are some of our top picks for heat sealable films.

Flxtite® AP-6

This heat sealable film has exceptional strength and sealing properties, which still maintaining clarity and visual appeal, making it an excellent choice for items that need a strong seal with shelf appeal.

Flxtite® AP-XH

Specialy designed for heavy duty items, this film boasts superior tear strength and durability for packaging heavy, oddly shaped, and sharp items.

Flxtite® AP-XGR

This irradiated shrink film offers high strength and tear resistance with a standardized opaque grey color to provide ultimate privacy and confidentiality for shipping personal, confidential, or light-sensitive items.

Heat Sealed Packaging Solutions

Heat sealed packaging solutions are designed to offer superior protection and preservation for a wide range of products. By using heat to bond two layers of plastic together, these solutions create strong, durable seals that safeguard the contents from external factors.

Flexible packaging is one of the most common heat sealed packaging solutions, used for products such as snacks, beverages, and pharmaceuticals. This type of packaging is lightweight, easy to handle, and provides excellent barrier properties, keeping products fresh and extending their shelf life.

Rigid packaging, another heat sealed solution, is used for items like food, cosmetics, and medical devices. This packaging type offers robust protection, making it ideal for products that require a higher level of durability and stability during transportation and storage.

Semi-rigid packaging, which combines the benefits of both flexible and rigid packaging, is often used for frozen meals and baked goods. This packaging solution provides the necessary strength to protect the product while offering some flexibility for ease of use.

By choosing the appropriate heat sealed packaging solution, manufacturers can ensure that their products remain safe, fresh, and intact throughout their lifecycle.

Heat Sealable Film Materials and Properties

Heat sealable films are crafted from a variety of materials, each selected for its specific properties that enhance the film’s performance in packaging applications. Common materials include polyethylene, polypropylene, polyester, and high grade polyolefins, all known for their heat resistance, flexibility, and durability.

Polyethylene is widely used for its excellent heat sealing properties and flexibility, making it suitable for a range of packaging types, from flexible pouches to rigid containers. Polypropylene offers higher heat resistance and is often used for packaging products that require sterilization or exposure to high temperatures, such as medical devices and ovenable food items.

Polyester, known for its strength and durability, is used in applications where puncture resistance and barrier properties are critical. This material is ideal for packaging products that need to be protected from moisture, oxygen, and other environmental factors.

The key properties of heat sealable films include heat resistance, which ensures that the seals remain intact at high temperatures; flexibility, which allows the films to be used in various packaging formats; and durability, which provides resistance to punctures and tears, ensuring the integrity of the sealed package.

By understanding the materials and properties of heat sealable films, manufacturers can select the best film for their specific packaging needs, ensuring optimal performance and product protection.

Seal Strength Testing for Packaging Equipment

Seal strength testing plays a critical role in ensuring the quality and integrity of heat-sealed packaging, a crucial part of safeguarding products during storage and transportation. Various methods are employed to assess the strength of heat seals, each providing unique insights into the packaging’s reliability.

The burst test, for example, measures the maximum pressure a seal can withstand before failing, making it essential for packaging containing pressurized contents. Another method, the creep test, evaluates how the seal behaves under a constant load over time, simulating real-world conditions that packaging may encounter. The vacuum dye test, on the other hand, involves creating a vacuum to detect any leaks in the seal, which is particularly important for products requiring aseptic conditions, such as surgical product packaging.

By implementing these testing methods, manufacturers can identify weaknesses or defects within the packaging, ensuring they meet industry standards and regulations. Robust seal strength testing not only enhances product safety and shelf life but also plays a vital role in the overall packaging development process, contributing to effective supply chain management and consumer satisfaction.

Heat Sealable Films: In Conclusion

Heat sealable films are an excellent choice for high-quality protection when you need the extra strength. Choosing the right heat sealable film will depend heavily on the type of products you are sealing, your equipment, and the packaging uses. It’s best to consult with a packaging specialist who is knowledgable about the technical details of each film to guide you to the best heat sealable film for your product.

Still, that is no replacement for checking the technical data sheet and performing variuos packaging tests to ensure the durability and effectiveness of your heat-sealed packaging. If you’re looking to improve your packaging solutions, contact the experts at Folene Packaging to discuss which heat sealable film is best suited for your specific application. Their team is ready to help you find the optimal solution for your packaging needs.