When choosing a shrink packaging film, there are so many options to select- irradiated vs non-irradiated, high gauge vs low gauge, and centerfold shrink film rolls vs singlewound. What is centerfold film, and how does it compare to other options? Folene packaging presents everything you need to know about centerfold film to make an informed decision for your packaging process.

What is Centerfold Shrink Film?

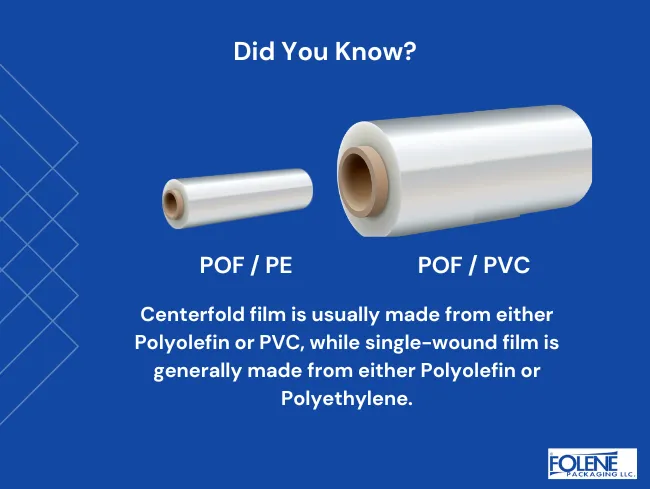

Centerfold shrink film means that the shrink film has been folded over once lengthwise before being wound into a roll. This creates a basic pocket that items can be inserted into and then sealed and shrunk to size for many easy shrink-packaging applications. Centerfold film is usually made from polyolefin shrink film (or PVC film), while single-wound film tends to be made from either polyolefin or polyethylene shrink films.

This is in contrast to singlewound shrink film, which is just a single flat layer of shrink film wound into a roll. Centerfolding the film provides specific packaging benefits and is better suited to certain packaging processes than singlewound. Usually, the film itself is available in the same grades, lengths, gauges, and properties in both centerwound and singlewound. Both centerwound and singlewound films are compatible with a wide range of products- from electronics to frozen pizzas. The main difference is purely in how the film is packed and sold, which lends itself better to some packaging scenarios than others.

Benefits of Using Centerfold Shrink Film

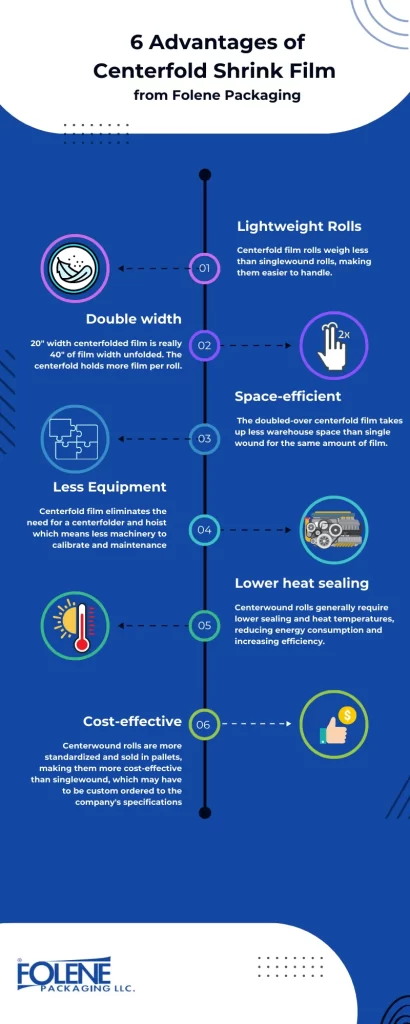

There are several benefits of using centerfold polyolefin shrink film over single wound, which is why many manufacturers tend to prefer centerfold for packaging. Here are some key benefits:

Lightweight rolls- centerfold film rolls weigh less than singlewound rolls, making them easier to handle.

Double width- 20″ width centerfolded film is really 40″ of film width unfolded. The centerfold holds more film per roll.

Space-efficient- The doubled-over centerfold film takes up less warehouse space than single wound for the same amount of film.

Equipment-efficient: Centerfold film eliminates the need for a centerfolder, which takes singlewound film and folds it over lengthwise during the packaging process. Additionally, the heavier singlewound rolls may require a hoist to put them into place on the packaging machinery. These extra pieces of equipment need to be recalibrated for a precise lengthwise fold with each film roll changeover and require maintenance like any other machine. Centerfold film circumvents the need for this equipment, streamlining operations.

Centerwound rolls generally require lower sealing and heat temperatures, reducing energy consumption and increasing efficiency.

Centerwound rolls are more standardized and sold in pallets, making them more cost-effective than singlewound, which may have to be custom ordered to the company’s specifications. Centerfold films can be more affordable, helping businesses save on packaging costs.

Applications of Centerfold Shrink Film

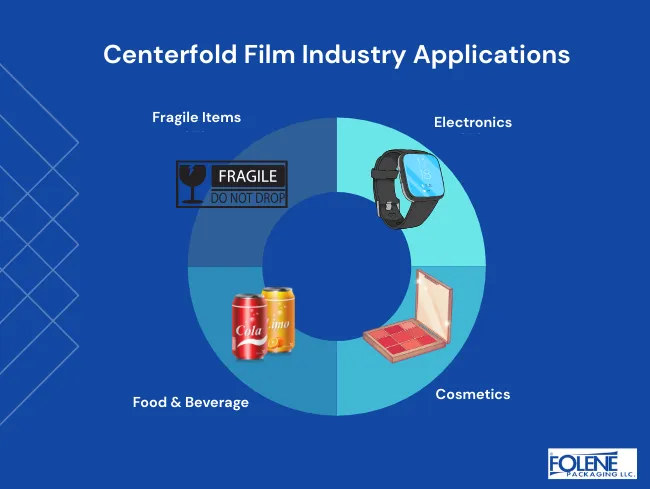

Centerfold polyolefin shrink film is an excellent option for packaging products across a wide range of industries. Let’s take a look at some of the packaging applications of centerfold film.

Wrapping electronics, such as cables and wires, for protection and organization.

Packaging food and beverages, including pizzas, baked goods, and snacks.

Securing bath bombs and other cosmetics for shipping and storage.

Protecting fragile items, such as glassware and ceramics, during shipping.

How do you decide between a center-wound film and a single-wound film?

Whether centerfold film or single wound is better for packaging your products will depend on two main factors:

The packaging aesthetic you want to achieve

Your packaging equipment/settings

Consider the look of the final packaged product on the retail shelf. Centerfolded film will yield a package with visible seal marks on the top and sides of the package. Single-wound film packages will have seal marks on both sides and the bottom of the package. Which will lend itself to a better package aesthetic for your particular product? This should help with the decision-making process.

The other factor to consider is the sealing and shrink equipment you have. Centerfold films are compatible with most, but not all, types of packaging equipment. L-Bar machines and tabletop sealers are particularly well-suited to centerfold film, as they create a snug seal around the three open edges of the film. However, singlewound film may be better suited to very high-speed packaging equipment, as there is less roll changeover, which means higher production efficiency overall. If production level is a high priority, then singlewound film may be a better choice.

Using Centerfold Shrink Film with L Bar Sealer

Centerfold film pairs well with L bar sealers, which create a top and bottom effective 3-sided seal around the product. These machines are easy to use and operate, with a simple and efficient sealing process. Additionally, with fully manual to semi-automatic options, it is possible to ramp up production levels to meet increased quantity demands.

Shrink Wrap Techniques with Heat Gun

Centerfold film is also compatible with manual heat guns for shrinking and sealing the film. This low-output manual process is suitable for low-production needs. The pre-folded film makes it easier to properly position the item before applying heat and removes the need to bunch the film together excessively to achieve full coverage. Apply heat from the gun evenly to avoid wrinkles and creases in the film. Remove excess film to create a smooth finish on all sides.

Customization Options for Centerfold Shrink Film

Folene Packaging offers all grades of shrink film in both centerfold and single-wound formations for ultimate flexibility. They are available in a range of different gauges and widths to suit specific packaging needs. The film can easily be customized with printed logos, images, and text for branding and marketing, with custom sizes available to meet different packaging requirements. Our sustainable lines of Ecolene® shrink film, including our biodegradable film and PCR-content film option as centerfold shrink film rolls.

Choosing Centerfold Shrink Film: In Conclusion

Centerfold shrink film is a versatile, efficient, and cost-effective packaging solution that caters to various industries. Its numerous benefits, applications, and high availability make it an ideal choice for businesses aiming to reduce costs and enhance efficiency. By adhering to proper usage and safety guidelines, companies can maximize the advantages of centerfold shrink film and improve their operations. Not sure if centerfold film is right for your packaging application? Get in touch with our specialists at Folene Packaging, and we’ll be happy to guide you to the right film for your needs.