Today, there is a broad selection of packaging options. How can a purchasing director decide which material is best for the product? The purchase department grapples with the cost and quality of packaging and delivery risks, and distributors struggle with supplier performance. While the cost of packaging materials is an important factor, choosing inferior-quality packaging in the interest of economizing can have disastrous effects.

That’s why anyone who deals with packaging for retail sales should know the advantages and disadvantages of biaxially oriented polypropylene (BOPP). Knowledge is power when it comes to deciding on the best packaging for your products. BOPP film’s many strength advantages make it a high-quality packaging film choice for many suppliers. Using a stronger wrapping material makes all the difference in packaging and delivering retail goods, ensuring product quality and integrity from production to consumer.

What is Biaxially Oriented Polypropylene?

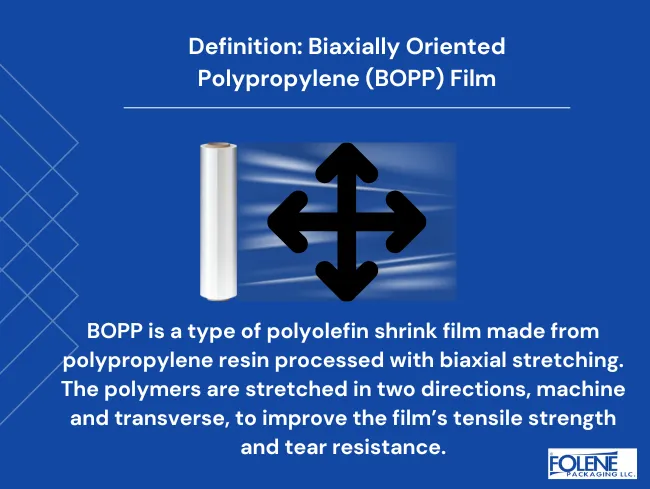

BOPP (Biaxially Oriented Polypropylene) film is a commonly used category of plastic film. It is made from polypropylene resin processed with biaxial stretching. It is a thermoplastic polymer and one type of plastic made from polyolefins. The properties of BOPP make it one of the best packaging films.

BOPP is a biaxially oriented polymer. The BOPP film is produced by extruding the raw material to make it into a roll of film. The film undergoes biaxial orientation, where the polymer chains are stretched in two directions, or ‘bi-axially’: in both machine and transverse directions. This process improves and strengthens the molecular chain orientation, resulting in a stronger, more tear resistant film. Different interventions, such as chilling, are sometimes added. The process gives BOPP film unique properties, such as high tensile strength, clarity, ultra-glossy appearance, and barrier properties.

The Development of BOPP

BOPP was manufactured in the early 1960s following suppliers’ demands for strong, flexible, and transparent packaging—perhaps a new type of plastic film. The biaxial film orientation process enables manufacturers to package products better, reducing weight and breakages while in transit.

Today, BOPP is one of the most widely used plastic films worldwide. It is useful in many industries for packaging, labels, adhesive tapes, and gift wrapping. It is safe for food packaging and commonly used for cigarette package overwrap.

According to Market Research Future, more people are using biaxially oriented polypropylene film. The value of the BOPP industry in 2024 is $16.63 Billion, and the industry is projected to grow to $22.8 Billion within 8 years by 2032. properties of BOPP make it a good packaging material. Direct food packaging makes up 58% of BOPP film. Retail demand for BOPP bags is expected to increase at a CAGR of 2.40% through 2034

5 Advantages of BOPP Films

Aside from the fact that BOPP films are safe for food packaging and may come into direct contact with the food packaging, BOPP labels adhere to strict standards, allowing them to be used for labeling and packaging in the health and beauty industry.

It’s easy to understand why. Here are some benefits of BOPP:

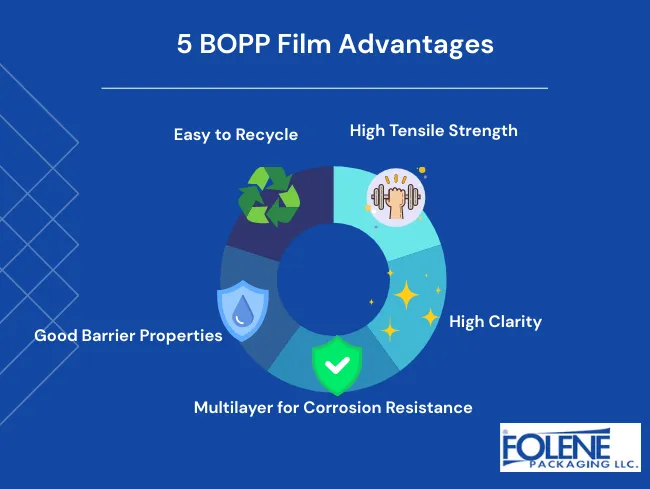

1.Higher level of tensile strength

BOPP films have high tensile strength, and biaxial stress resistance, which means there is an even distribution of force on the packaging. BOPP packaging is resistant to tears and punctures. This is useful for items that have sharp edges or need extra protection. The strength of BOPP films makes them a good choice for tamper-evident seals.

2.Biaxial orientation leads to enhanced clarity

The manufacturing process of BOPP gives the film excellent clarity and transparency. This is ideal for pharmaceutical use and gift or display wrapping where visibility is important.

3.Biaxiality in BOPP films means good barrier properties

Biaxially oriented films have dimensional stability and stiffness, which gives BOPP packaging an advantage for hygiene and cleanliness—especially important where items need protection from moisture or oxygen. Its tight seal offers puncture resistance and locks in aroma and flavor.

4.Layering gives better properties, yield strength and tensile strength

You can add a metallic layer to BOPP (multilayer film) to ensure resistance to corrosion and deterioration when in contact with oils, grease, and chemicals. BOPP film is popular for industrial and outdoor uses, such as protecting electrical and metal mechanical parts against rust and moisture. It can also be a good substitute for aluminum foil, replacing expensive and toxic cellophane and PVC.

5.Biaxial orientation gives a lower melting point and lower density

The best aspect of BOPP films and labels is that BOPP plastic film is recyclable and reusable. It’s easier to recycle because it becomes softer at lower temperatures. Additionally, the films are usually thinner as the biaxial properties mean you can make films that have lower thickness, yet better strength properties.

Printing on BOPP Labels and BOPP Tape

You can print on BOPP labels using either water-based or solvent-based inks, making them a versatile choice for labeling applications.

The surface of BOPP films can be modified to improve printability and adhesion. Of course, you can print on BOPP tape, giving small businesses an inexpensive, branded option for sealing packages.

Surface modification in BOPP films is enhanced by “corona treatment,” which promotes molecular adhesion and helps layers stick together. This chemical treatment increases bonding strength, resulting in better print quality.

Unlike other label materials, BOPP labels resist smearing and fading, giving them the edge in custom-printed product packaging and labeling.

Aside from printing on BOPP films, special finishes, such as silk-touch or matte, allow manufacturers to produce high-end products that consumers love to buy. Crystal clear printing enhances the complete effect.

High-Tensile BOPP Films

BOPP film is known for its ability to withstand tensile stress. Its strength comes from it being drawn in the machine direction with heated rollers and then in the cross (or transverse) direction within a heated environment. This aligns the polymer chains in the most robust way. Its high-tensile properties lend it to be commonly used for packaging that requires:

moisture resistance

optical clarity, and

high tensile strength

Examples of BOPP uses:

Food and drink packaging

Seals on wine bottles

Medical tools

OTC medicines

Personal care products

Tamper-evident films for baby food

Easy-open, environment-friendly pet food storage

When a packaging film is biaxially-oriented and is also cross-linked, it produces a superior film. Depending on the type of product and the packaging requirements for that item, different grades of film will work better. For example, Folene’s Flxtite® AP-XH biaxially oriented film is well suited to evenly wrapping heavy duty items, while Folene Packaging’s Ecolene® AP-XPCR offers a biaxially-oriented polyolefin film with high PCR content and a positive environmental impact. The notable strength in both films comes from stretching with the cross direction technique. However it remains important to choose the right film for the product.

Why Choose BOPP Over Other Packaging Types?

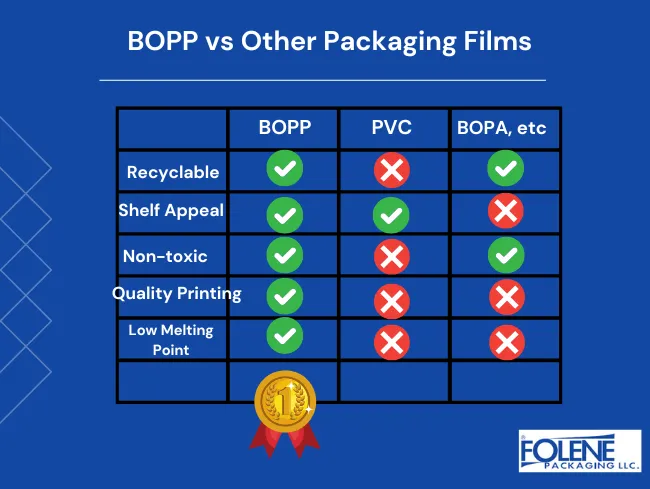

BOPP films have several advantages over other plastic films, such as polyester films, BOPA (Biaxially Oriented Polyamide) film, and PVC films:

PVC is usually considered a dangerous plastic as it contains a lot of plasticizers, which contaminate everything in the recycling stream. Although that might change one day, it is one of the most complex plastics to recycle and is usually very toxic.

PVC has a reputation for being difficult to work with. Printing on PVC can often fail and result in low-quality printing. With BOPA film, vulnerability to moisture absorption and film deformation can lead to poor print quality, especially where there is a high level humidity.

PVC and other non-PE films have a higher melting point, making recycling more expensive and challenging.

The FDA tags PVC plastics as “food safe,” but they contain phthalates statistically associated with obesity, asthma attacks, and birth defects.

Biopolymer-derived films have poor barrier properties and, therefore, poor commercial viability. This includes plastic films made of natural polymers such as gelatin, casein, starch, or cellulose. Some other polyester films do not stand up to external pollution.

FAQs About Biaxially Oriented Polypropylene

What is the tensile strength of BOPP film?

A material’s tensile strength is the measurement of the maximum stress that BOPP can withstand before failure (tearing, splitting or puncture). When testing the material, physicists measure ‘tensile strength at break’ for the BOPP film when the film is forced to break, calculating force applied at the break of the film, divided by the film’s initial cross-sectional area. BOPP is tested with biaxial tension testing. The equation for tensile strength is: s = P/a (s is the tensile strength, P is the force needed to break and a is the cross-sectional area of the film).

The first measurement is Machine direction MD, the second measurement is Transverse direction (TD). A typical result for Ecolene® AP-XPCR is a tensile strength of 15-16 kpsi (MD-TD). Kpsi stands for the units of tensile strength – thousands of pounds per square inch (kpsi) or Newtons per square meter(Npsm). The tensile strength of plastic film varies from one type of plastic to the next, and as a result of the techniques used in the processing. However, sometimes BOPET films can have higher tensile strength that BOPP films.