Mattresses are expensive items that need excellent protection during shipping and storage. If not adequately protected in transit, porous mattresses can collect dirt, absorb moisture, and harbor bacteria. Mattress manufacturers want to ensure that their merchandise arrives to stores, warehouses, and customers intact. So, what is the best plastic wrap for a mattress? Folene Packaging’s experts present our top picks.

Choosing the Right Mattress Protection

There are a few important points to consider when wrapping mattresses. These will guide your decision of which plastic wrap to use for mattresses.

Size: What sizes of mattresses are you wrapping? Queen size, king size, twin size, full-size, toddler mattresses, or crib mattresses? Take the measurements of the largest and smallest sizes to ensure that they are compatible with the shrink film dimensions.

Material: You want to choose a high-performance film with high tear resistance and moisture barrier.

Film Gauge or Thickness: Consider how thick you need the film to be. The thicker the film (the higher the gauge), the better the tear resistance and protection.

Sustainability: Choosing an eco-friendly plastic wrap for mattresses makes a loud statement to customers who value sustainability. Biodegradable films and wraps with high PCR content can deliver excellent performance while still being good for the environment.

Cost: Consider your packaging budget and the price point of each potential plastic wrap. Which is most cost-effective? Can a lower-grade film still meet performance requirements at a better price point?

Folene Packaging’s Top Picks for Plastic Mattress Wraps

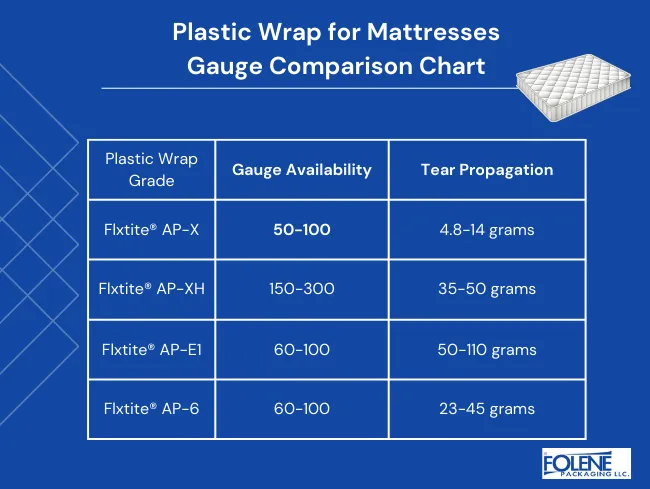

1. Best Overall Heavy-Duty Shrink Wrap: Flxtite® AP-XH

Specifically designed to package heavy duty and oversized items like mattresses, Flxtite® AP-XH has outstanding strength and tear resistance, perfect for protecting mattresses from the warehouse to the consumer.

2. Best Cost-Efficient Protection: Flxtite® AP-E1

Flxtite® AP-E1 offers excellent tear resistance with reasonable optics. A practical and slightly more cost-efficient option for tight packaging budgets.

3. Best High-Speed Applications: Flxtite® AP-6

With high tear resistance and uniquely well suited to high speed packaging equipment, Flxtite® AP-6 is an excellent choice for high-volume mattress manufacturers.

4. Best Optics & Universal Machine Compatability: Flxtite® AP-X

Flxtite® AP-X Crosslinked Shrink Film boasts outstanding puncture resistance, universal machine compatibility, and excellent optics. This high clarity and gloss film is suitable for in-store retail display to protect mattresses from user test damage.

Moving and Storage Tips

Leverage these tips to ensure ultimate protection for mattresses in transit, where tears and damage are most likely to occur:

Use a dolly or other moving equipment to transport your mattress and box spring safely

Consider using a mattress bag or cover with handles or straps for easy moving

Store your mattress and box spring in a dry, clean area to prevent dust and dirt buildup

If the storage area is not 100% waterproof, use plastic bags or trash bags to cover mattresses and box springs in storage.

Common Mistakes to Avoid

Avoid these common mattress packaging errors to ensure your products remain well-protected throughout transportation and storage.

Using a plastic wrap that is too small for the mattress size

Using a plastic wrap with a gauge that is too low: The thickness of the wrap is essential for adequate tear-resistance. A plastic wrap that is too thin will tear easily in transit, leaving the mattress exposed to dirt, moisture, and contaminants.

Not checking for tears or punctures in your mattress bag or cover before moving or storing. It’s essential to have standard procedures in place to check the wrapped mattresses periodically for tearing during transportation. This is the best way to avoid product damage, as catching tears early means you can rewrap the mattresses before any damage occurs.

Tips for Wrapping a Mattress in Plastic Wrap

Use plastic wrap with adequate dimensions to cover the mattress completely

Ensure that the wrap seals completely and shrinks evenly over the mattress. A packaging test run is essential when first using a new plastic wrap on your packaging equipment. Review the test run results carefully to catch and troubleshoot any packaging issues.

Use a high gauge film for ultimate tear resistance.

Consider using a mattress cover, encasement, or other secondary packaging for added protection

Use a dolly or other moving equipment to transport your wrapped mattress safely

Conclusion

Choosing the right plastic wrap or mattress bag for moving and storing mattresses can be a challenging task. Consider the size, material, and features of the wrap to ensure the best protection for your mattresses and box springs. Still unsure which is the best plastic wrap for a mattress? Reach out to our packaging specialists at Folene Packaging, where we are committed to helping you find the right materials for a successful storage experience.