7 Benefits of Perforated Packaging

Introduction to Perforated Packaging

Perforated packaging is a type of packaging that features tiny holes or slits in the material, allowing for ventilation, easy access, and visibility of the product. This type of packaging is commonly used in the food industry, retail packaging, and e-commerce packaging. Perforated packaging boxes, containers, and blister packets are designed to provide a convenient and user-friendly experience for consumers.

The packaging industry has seen a shift towards perforated packaging due to its numerous benefits, including cost-effectiveness, sustainability, and customization options. By incorporating tiny holes, perforated packaging ensures that products, especially those in the food industry, remain fresh and well-ventilated. This innovative approach not only enhances the shelf life of products but also supports eco-friendly practices by reducing the need for excessive packaging materials.

As e-commerce continues to grow, the demand for perforated packaging solutions that offer easy access and improved user experience is on the rise, making it a vital component in modern packaging strategies.

Why Use Perforated Packaging?

Perforated packaging involves creating tiny holes or slits in packaging materials to enhance usability, convenience, and freshness, depending on the application, and products can benefit greatly from these enhancements. Folene Packaging explores several applications for perforated packaging, as well as the pros and cons of popular perforation methods.

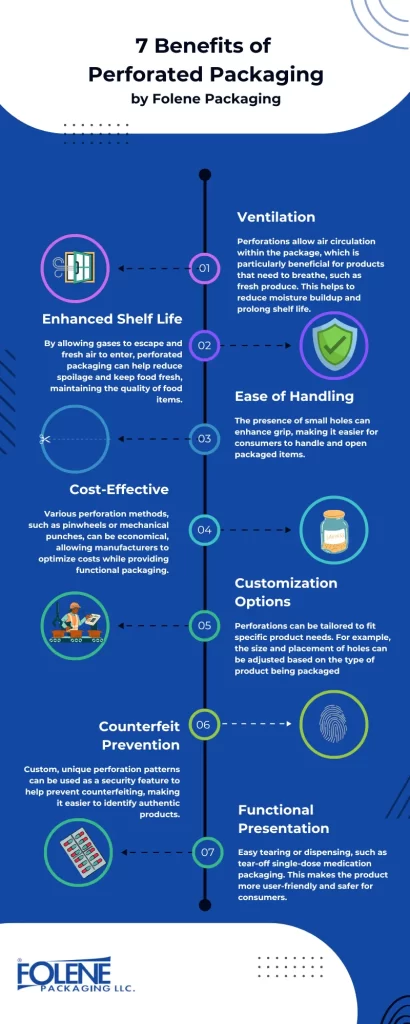

7 Benefits of Perforated Packaging

Ventilation: Perforations allow air circulation within the package, which is particularly beneficial for products that need to breathe, such as fresh produce. This helps to reduce moisture buildup and prolong shelf life.

Enhanced Shelf Life: By allowing gases to escape and fresh air to enter, perforated packaging can help reduce spoilage and keep food fresh, maintaining the quality of food items. This is an excellent alternative to MAP packaging, which is not always compatible with the food item.

Easy Handling: The presence of small holes can enhance grip, making it easier for consumers to handle packaged items.

Customization: Perforations can be tailored to fit specific product needs. For example, the size and placement of holes can be adjusted based on the type of product being packaged, supporting unique custom packaging and recognizable branding.

Cost-Effectiveness: Various perforation methods, such as pinwheels or mechanical punches, can be economical, allowing manufacturers to optimize costs while providing functional packaging.

Counterfeit Prevention: Custom, unique perforation patterns can be used as a security feature to help prevent counterfeiting, making it easier to identify authentic products.

Functional Presentation: Some perforated designs enable easy tearing or dispensing, such as tear-off single-dose medication packaging. This makes the product more user-friendly and safer for consumers.

Overall, perforated packaging provides a balance of functionality and consumer appeal, making it a popular choice across various industries.

Top Perforation Methods

There are several different methods for perforating packaging. Here we explore the most popular methods and their ideal applications.

1. Unheated Pinwheels

This method is simple. The film passes through a spiked roller that pokes “volcano” shaped holes in the production line before shrinking. It can create a series of small holes as the film passes over the pinwheel, and is by far the cheapest perforation method. However, unheated pins can tear holes that may elongate during shrinking, potentially leading to customer dissatisfaction. Pinwheel holes can also close up when exposed to different temperatures and are not suitable for all applications.

2. Heated Pinwheels

This method introduces heat and melts through the film, creating a reinforcing ring around each hole. Holes maintain their shape better during shrinking and appear less like defects. However, sufficient heat control is necessary to avoid excessive melting, which can ruin the packaging entirely.

3. Mechanical Punches

Can create individual or multiple holes with customizable hole size and placement. In addition, creating unique die cut perforated hole designs on the package can promote branding and help prevent counterfeiting. Mechanical punching is a relatively inexpensive perforation method, but more expensive than pinwheels. One of the main drawbacks to this method is it requires more maintenance to ensure clean cuts and manage the scrap (chads) to prevent contamination, buildup, and machine issues.

4. Lasers

This method produces high precision, nearly invisible holes, with no wear on machine parts, which reduces maintenance. The hole size, design, and frequency are all programmatically adjustable, allowing for efficient modifications. However, initial setup costs are much higher compared to other methods, as laser perforation requires specialized equipment.

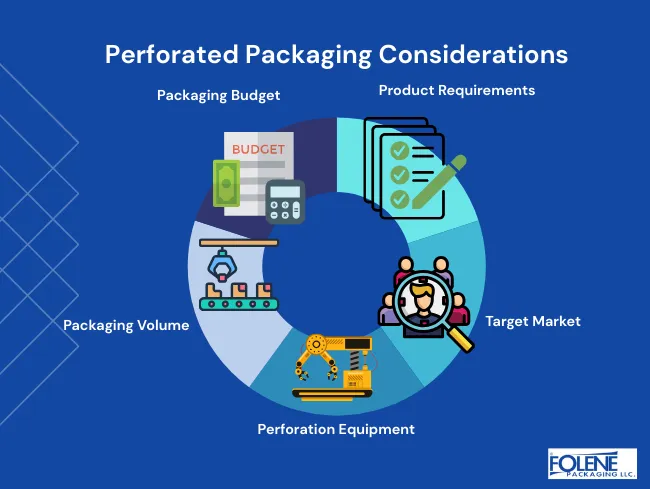

Each perforation method offers unique advantages, but the best choice depends on the product’s specific packaging requirements and cost considerations.

Custom Packaging Options: Ordering Pre-Perforated Shrink Film

Custom packaging options allow businesses to create unique perforated packaging designs that meet their specific needs and offer branding opportunities. Depending on the packaging application, different perforation sizes and patterns may work better than others. Custom perforation allows businesses to create packaging that is both functional and visually appealing. Folene Packaging offers custom perforated packaging solutions that can be tailored to the needs of various industries. We can customize perforation options on our film rolls to meet your unique packaging requirements and ensure high performance. Contact a Folene Packaging representative today to discuss your perforated shrink packaging needs.

Applications in Different Industries

Perforated packaging is widely used in the food industry for packaging bakery items, baked goods, fresh produce, and other perishable items. In the pharmaceutical business, perforated blister packets allow easy access to medication and are essential for safe handling. Perforated packaging is also used in e-commerce for packaging consumer goods, providing easy access and convenience for customers.

Perforated shrink film is particulaly beneficial for packaging air fresheners, deodorants, and other personal care items where ventilation, visibility, and ease of access are all essential.

E Commerce Packaging Solutions

Perforated packages are ideal for e-commerce businesses, as they provide easy access and convenience for customers. Perforated packaging is suitable for a wide range of products, including food, consumer goods, personal care items and pharmaceuticals. Perforated packaging solutions are designed to reduce waste and support sustainable practices in e-commerce packaging. The easy-open packaging design as well as the minimal packaging material reduces waste and appeals to eco-conscious consumers. Perforated packaging is lightweight and travels well, offering a cost-effective and efficient way to package e-commerce products, improving customer satisfaction and loyalty.

Pharmaceutical Business Applications

Perforated packaging is widely used in pharmaceuticals. Perforated blister packets are standard to give patients and healthcare providers easy access to a single dose of medication at a time, allowing them to easily pop out their doses. This simple yet crucial feature helps reduce dosage errors, while ensuring safe handling and storage of medication. Furthermore, the grab-and-go nature of perforated single-doses ensures patients are more likely to tear off a dose they’ll need to take soon before heading out the door, reducing missed doses.

Perforated packaging is essential for maintaining product cleanliness and extending shelf life in the pharmaceutical industry. Furthermore, perforated packaging is also used for packaging medical devices and equipment, providing a safe and convenient way to store and transport them.

Alternatives to Traditional Packaging

Perforated packaging can be a viable alternative to traditional packaging methods depending on the application, using minimal resources, reducing waste, and supporting eco-friendly practices. Perforated packaging solutions can be designed to meet the specific needs of various industries, including food, pharmaceutical, and e-commerce, offering several benefits. Perforated packaging offers a unique and functional way to package products, enhancing product visibility and ventilation at cost-effective price point.

Branding and Marketing

Perforated packaging provides businesses with a unique opportunity to enhance their branding and marketing efforts. Custom packaging designs can be created to meet the specific needs of a business, improving product visibility and recognition. Perforated packaging branding ideas include creating a logo on the package from perforations, writing a tagline, message, or symbol with perforations. Perforated packaging solutions can be used as a storytelling canvas to create an emotional connection with customers, improving customer loyalty and satisfaction. They offer a cost-effective and efficient way to make packaged products stand out on the shelf.

Perforated Packaging: Stepping Up Customer Satisfaction

Perforated packaging is designed to improve customer experience and satisfaction, providing easy access to the product inside and convenience, in addition to better ventilation and visibility. Many brands leverage perforation in packaging across industries to package products that require ventilation and visibility. Perforated packaging solutions are created to meet the specific needs of customers, improving product freshness and extending shelf life. They offer a unique and functional way to package products, enhancing customer loyalty and satisfaction. Contact Folene Packaging today to create a memorable custom perforated packaging experience for your products and your customers.