What is BRCGS Certification?

BRCGS certification is a globally recognized standard for food safety, benchmarked to the Global Food Safety Initiative (GFSI). Although it was initially named BRC (for the British Retail Consortium- the UK trade organization that first developed the standard), the current name stands for Brand Reputation through Compliance Global Standard, which reflects its more global nature.

BRCGS provides a practical framework for food manufacturers to achieve the highest levels of consumer food safety, including HACCP, traceability, and quality management systems. The certification is not limited to European companies; it serves as a globally recognized food and safety certification program. The BRCGS START! Program is an introductory program designed to assist small and medium-sized operations in aligning with BRCGS Food Safety Certification. Folene Packaging brings you all the information you need about BRCGS certification and why food companies worldwide should consider getting certified.

Benefits of BRCGS Food Safety Certification

BRCGS is the international gold standard when it comes to consumer food safety, quality, and compliance. Here are some of the main benefits of BRCGS certification:

Demonstrates compliance with comprehensive food safety initiatives

Many top U.S. and EU retailers require BRCGS certification as a pre-requisite for consideration in carrying a food product in their store chain.

Increases customer confidence and assurance of product quality and safety.

Provides a competitive advantage in the market.

Enhances brand reputation as safe and reliable.

Expands market access.

These significant benefits are each compelling reasons for food manufacturing companies to get certified and level up their food safety practices.

Understanding BRCGS Standards

The BRCGS standard describes three levels of involvement:

Enrollment program

Announced audit program

Voluntary unannounced program

The standard sets out requirements for processed foods and other products, covering seven sections, including senior management commitment, food safety plan, and product testing. The standard requires organizations to implement a system for producing safe products and meeting customers’ expectations. It also covers site standards, product control, operations & processes, and personnel. The highly thorough nature of the BRCGS and its accompanying audit process and certification is a significant reason why it is globally considered the gold standard in food safety.

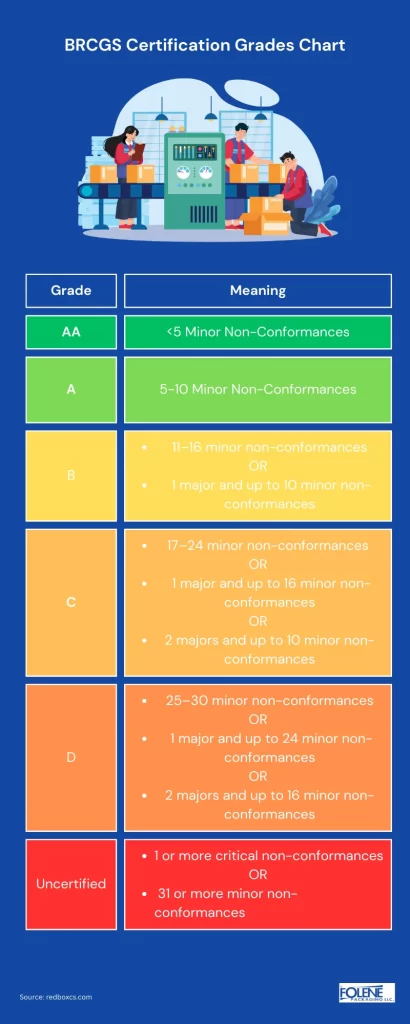

BRCGS food safety certification is awarded in 6 different grades, ranging from AA (excellent) to Uncertified. Each grade indicates a higher or lower level of compliance with BRCGS food safety standards.

Preparing for BRCGS Audit

Decided to start aligning your processes with BRCGS standards? That’s a smart move. Here are some tips to help your facility prepare for the BRCGS Audit.

Assemble a multi-disciplinary food safety team with members from quality assurance, technical management, operations, and engineering.

Ensure team members understand HACCP principles and the team leader demonstrates both knowledge and competence.

Implement a holistic approach to food safety with a diverse team.

Comply with BRCGS requirements for team composition.

Conduct internal audits annually, with at least four separate evaluations per year (once per quarter).

These tips can help prepare your facility’s processes and team to meet the rigorous BRCGS standards and pass the audit with flying colors.

The Certification Audit Process

Participate in an on-site BRCGS audit, including an opening meeting, production facility inspection, and document review. Demonstrate compliance with BRCGS certification requirements at each step in the production process, giving the auditor easy access to all relevant information and facilities. Ensure all necessary documents and records are up-to-date to facilitate a smooth and prepared audit process.

Preventing Food Fraud with BRCGS

Food fraud is a serious issue in food manufacturing and can have criminal implications for company management if found to be intentional. Accidental food fraud can also occur through carelessness and negligence, potentially exposing consumers to harmful substances, mislabled and misleading products, and diminishing consumer trust in the company’s integrity and reliability. BRCGS standards incorporate strict procedural safeguards against accidental and intentional food fraud:

Food Safety: Hazard Analysis and Critical Control Points (HACCP) system, designed to prevent unintentional adulteration.

Food Defense: Threat Assessment Critical Control Points (TACCP), which focuses on preventing intentional adulteration stemming from ideological or behavioral motivation.

Food Fraud: Vulnerability Assessment and Critical Control Points (VACCP), designed to prevent intentional, economically motivated adulteration.

Implementing a BRCGS food safety program includes these measures to prevent food fraud from all directions and promote food safety, quality, and reliability.

BRCGS Packaging Materials

BRCGS also has standards for packaging materials, both for those used to package food and beverage items and more generalized packaging material applications. Ensure compliance with BRCGS packaging materials standards to increase your certification chances and align your packaging with globally recognized gold standards for product safety, quality, and operational performance.

Implement a supply chain management system to ensure the integrity of raw materials. Sustainability and waste management are two major concerns in BRCGS packaging standards, so pay attention to your packaging materials and processes. For example, plastic pellet loss prevention is an additional optional audit that tests and certifies companies for sustainable packaging practices- ensuring that pre-production plastic waste does not occur unnecessarily. Conduct regular audits to ensure compliance with packaging materials requirements.

Working with a Certification Body

Choose a BRCGS-registered Certification Body for your audit. Consider the certification body’s rating from BRCGS (1-5 stars). Ensure the certification body provides a comprehensive audit service. You should also consider the costs associated with BRCGS certification, which can weigh in around $13,000, excluding travel expenses. Although purchasing the BRCGS standards manual itself is inexpensive (under $200), the audit and pre-audit processes are expensive, each stage costing around $6,000, depending on the certification body’s particular pricing.

The Closing Meeting and Certification

To conclude the BRCGS audit process, you will need to participate in a closing meeting to discuss audit results and any non-conformities. It is imperative to address any non-conformities and corrective actions identified during the audit within 28 days of the audit. Important actions include conducting a root cause analysis to identify the source of the issue and implementing preventive actions to prevent reoccurrence. The auditing team will reevaluate how you addressed non-conformities after 28 days and issue your certification within 42 days of your initial audit date if your company qualifies for BRCGS certification.

Maintaining Certification and Continuous Improvement

Continuously develop and improve your food safety and quality system, striving to uphold and increase the integrity of your operations in comparison with BRCGS standards. Provide ongoing training for your team and conduct regular internal audits to ensure compliance at every level of production, quality control, and management. Verify ongoing compliance with BRCGS certification requirements and ready your facility for recertification. Depending on the grade of certification your company received after the initial audit, you may need more or less frequent audits to maintain or renew your certification.

Conclusion

BRCGS certification is a valuable asset for food manufacturers, demonstrating compliance with comprehensive food safety initiatives and gaining access to top U.S. and EU retailers. Food manufacturers can achieve food safety excellence and maintain certification by understanding BRCGS standards, preparing for audits, and working with a certification body. Folene Packaging is committed to helping companies find sustainable food-grade packaging solutions and processes that promote food safety and compliance. Contact us today to find out how we can assist you in making your food packaging operations safer, smoother, and more compliant.