10 Advantages of Printing on Plastic – Add Wow! to Your Packaging

Meet Ordinary Joe. He runs an ordinary business, producing ordinary personal care cosmetics, such as ordinary shampoo for ordinary people. His profits? Ordinary. The issues his company faces are surprise surprise, not standing out from the crowd enough to make an impact on the cosmetics market, and producing a lot of cardboard waste – brown cardboard boxes and brown corrugated box dividers.

One day, Ordinary Joe discovers that by printing on plastic, he can revolutionize his entire packaging strategy. He throws out the cardboard boxes, replacing them with colorful, mighty but economical plastic film and wrapping the bottles with attractive, shrink-to-shape films. Cases of shampoo now come with an itty-bitty cardboard tray and polyolefin shrink film that holds the bottles snugly and safely until they reach the retail shelves. Goodbye drab, hello shelf appeal; goodbye mountains of waste, hello better packaging – all through printing on plastic film. Joe, no longer ordinary, resolves both problems, turning them into advantages.

What is printing on plastic?

Printing on plastic means printing directly on your packaging film, bottles, boxes, or containers. It includes printing on plastic sheets.

You can print on different types of plastic and almost every kind of flexible packaging film, including:

PVC

Polycarbonate

PLA

TPU

BOPP

BOPET

BOPA

Aluminum foil stamping

Polyolefin (POF)

Polyethylene ( PET) and its derivatives, such as PETG and

Nylon.

Printing on Plastic – Or Not

Printing on plastic wrapping using process printing, such as printing on shrink film, is the most economical and efficient way to customize plastic wrapping. It is used mainly by high-capacity businesses for packaging consumer packaged goods since there is a minimum product amount (usually 50,000 units). Smaller companies use clear, non-printed films and apply printed product labels.

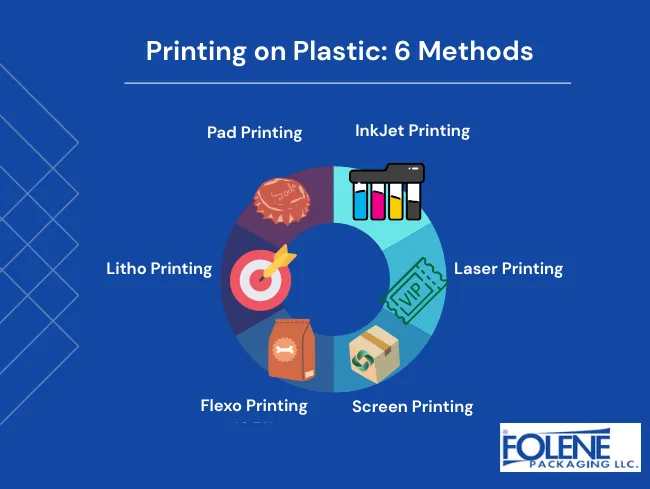

Methods of Printing on Plastic

There are several standard printing methods for printing on plastic surfaces:

InkJet printing – for accurate digital printing packaging. Digital inkjet printing is a customizable printing technology.

Laser printing – learn more here

Screen printing – usually used for artwork

Flexo Printing – for flexible print forms

Litho printing – also known as offset printing. The offset printing process allows sharpness and clarity that you don’t find with other printing methods. Using offset lithography is ideal for mass-production printing as the image is transferred from the file to the printing plate. It is adaptable for flexible print forms, so it is relevant to printing on shrink film.

Pad printing – also known as tampography, allows manufacturers to transfer a 2-D image onto a 3-D object, such as logos on bottle caps and instructions on cosmetic product packaging.

The type of printing and level of print quality you choose depends on your goals and the application.

Printing on plastic films is usually done using offset lithographic printing. The primary 2 types of printed shrink film are polyolefin and polyethylene films.

How Does Printing on Plastic Feature in Packaging?

The use of plastic shrink packaging alone has been increasing at a CAGR of 3.5%, and this is set to grow as the demand for packaged beverages grows globally. In Europe, the demand for packaged water is high, and in the Asia Pacific, the demand for packaged water and carbonated beverages is rising. Worldwide, Markets and Markets notes increased alcohol consumption, especially in China, India, and anywhere where youth have a disposable income.

Many forms of plastic packaging protect the product effectively while featuring other benefits. Several types of packaging incorporate printing on plastic.

Here are some ways that packaging uses printing on different plastic materials:

Covering a white-label product with your own-brand identification – example, print logo on shrink wrap and brand your fresh produce

Bundling items such as to promote a new product

Replacing a label to correct an error or change the language; sleeve replacement for bottled products

Creating multi-packs without trays – Example: a 3-pack of canned sweet corn or 2 soda bottles

Displaying regular display packaging for retail – especially consumer packaged goods

Providing secondary packaging for trays as tray overwraps

Printing e-commerce packaging for self-contained mailable products

Overwrapping: Box overwraps for gift-wrapping and protection – for example, personalized gifts

Ensuring confidentiality with opaque overwraps like AP-XGR for confidential and personal items

Switching to printed shrink-wrap packaging to become more sustainable

A distinct advantage of printing on plastic is the ability to wrap cases of shelf-ready packaging with colorfully branded, easy-to-identify graphics, such as on shelf-ready trays of tomato sauce. This allows retailers to load entire cases of products onto the retail shelves more efficiently.

Choose The Right Shrink Film For Printing

It is important to choose the right type of plastic wrapping for your products, such as printed shrink film. If you search for a list of top 10 suppliers of packaging, you can’t simply choose the first one listed. This is because each type of plastic has different features and benefits that will showcase, protect, or preserve your product in the way you need it to work. Sometimes, you may need to try more than one type of packaging before you settle on the one that works best for you.

If possible, source your packaging raw materials from someone near you or at least in the same country. This could save delivery times, and you will have someone to contact when researching packaging options.

Printing on Plastic: 10 Advantages in Packaging

Plastic packaging with printing offers many advantages. We have collected some of these inspiring advantages and categorized them.

1. Plastic packaging with print improves shelf appeal

Printing on plastic increases product individuality; print high quality images, logos and essential information clearly . It is also a way to provide graphics, advertising, warnings, instructions, and bar codes. Custom-printed packaging increases the perceived value of the product.

2. Colorful print on plastic wrappings enhances product visibility

Printing on all sides makes it easier for consumers to identify the product, giving the brand a strong voice. This helps consumers pick the right product off the shelf immediately and may influence greater sales.

3. Printed plastic wrap strengthens product integrity

Printed plastic wrappings are attractive and keep products tidy. The use of printed plastic overwrapping means the packaging will stay on the product for longer, protecting the product and keeping the product clean for longer. Manufacturers can ensure the original brand identity with an authentication seal. Printed plastic wrapping affords protection until opening the product – e.g. it keeps magazine pages uncrumpled.

4. Printing on plastics reduces packaging waste

Printing on plastics reduces the packaging footprint and is one of the most sustainable options due to the reduced amount of raw materials needed to produce effective packaging.

5. Printing on plastics for packaging can save expenses

Printed packaging on strong plastic films saves on transportation expenses due to the lighter packaging weight – especially with printed film for food packaging, which is a large portion of the retail sector. Space reduction – less space is required per item in delivery, storage, and disposal of packaging than bulky cardboard. Less packaging does the job effectively; manufacturers can save 50-75% of the cost of materials.

6. Custom-printed films are attractive, bright, and engaging

Offset printing is available in several colors – currently 6. When used to print on plastic for packaging, they are much more colorful and attractive than brown cardboard boxes. Digital printing on plastic film allows more options in mixing colors, and the digital transfer of the images yields clear images.

7. Printing on clear plastic offers flexibility in user options

Printing on clear plastic gives an adjustable choice of having a completely opaque coverage or leaving a clear window that displays the product. Whether printing on clear plastic film or opaque or designed films, manufacturers can usually use printed film rolls on their existing shrink-wrap equipment (minor changes may be required), saving capital expenditure costs.

8. Printing on plastic can reduce labor requirements

Good packaging means less labor is required by manufacturers and retailers. You can save workers time: they do not have to remove another packaging layer since the exterior packaging is ready for retail. Mechanical bundling of products with printed plastic packaging is used for multipacks and branded shelf-ready packaging.

9. Printing on plastics adds convenience for consumers

When two or more smaller packages are combined into a larger multi-pack, it is easier to pick several items off the shelf in one go – while identifying the product easily by its unique packaging design. Printing on plastic film for packaging foods gives sealed packaging that keeps the product safe from infestation and bugs; it prevents cross-contamination, conceals the contents for gifting, and controls odors for highly spiced or fragranced products.

10. Printed retail packaging for tamper evidence

Printed overwraps could prevent pilferage of small items and unintentional opening of the package in the store. They are also used to provide a tamper-proof seal for product safety and resistance to dirt or moisture. Overwrapping is used to add an unattached address label.

Folene Packaging Offers Plastic Film you can print on

Folene Packaging offers manufacturers and suppliers the broadest range of shrink films, suitable for packaging all types of products, including food, electronics, corporate gifts, and retail display items. By printing on plastics – and using the right type of roll stock, you can access marketing advantages to help improve sales and reach other marketing goals. Many people choose shrink film that undergoes a lithographic printing process because it is a clever way to increase your brand publicity while reducing your packaging footprint.

Speak to us to ask how to print on plastic, which of our films can be printed on, and which fits your needs best. We offer films in different gauges and those that are cross-linked and multi-layered for extra strength and reliability, micro-perforated for increased air circulations, and biodegradable films. By printing on plastic surfaces of your film packaging, you can add another dimension, taking your products to the next level!

Reach out to Folene Packaging today to find out more about printing on plastic films.

One Response