Many manufacturers and retailers do not know which packaging materials are fully compostable, which are less compostable, and which will virtually never decompose. There is growing global awareness of what compostable packaging options are available, and we might have said that manufacturers don’t know and they don’t care—but this is no longer true.

Experts predict that the market size for compostable materials used in packaging will grow. In 2022, the market was worth $88.73 billion. Within just 10 years, by 2032, it is expected to increase to $197.85 billion at a compound annual growth rate of 8.4%. That is almost twice the CAGR for recycling in the U.S., which experts expect will grow from around $3.95 billion in 2023 at a CAGR of 4.3% between 2024 and 2030.

What Does Compostable Mean?

Let’s define compostable. Compostable materials are organic materials that biodegrade and disintegrate into nutrient-rich soil at the end of their useful lives via the composting process. The finished compost is organic matter (sometimes tested for soil health) with many environmental benefits.

How composting works:

Composting is a natural process of biodegradation.

Organic materials decompose into nutrient-rich soil.

Microorganisms, heat, moisture, and sometimes worms assist.

The composting process can take several weeks to several months, depending on the materials and conditions.

In business, items that are compostable are a lot more meaningful than fruit and vegetable scraps or making a home compost pile. We are not talking about food scraps but mountains of packaging.

Packaging That Is Fully Compostable

Compostable packaging can be an effective yet sustainable alternative to the plastic packaging we grew up with, which is now choking our world.

What is compostable packaging?

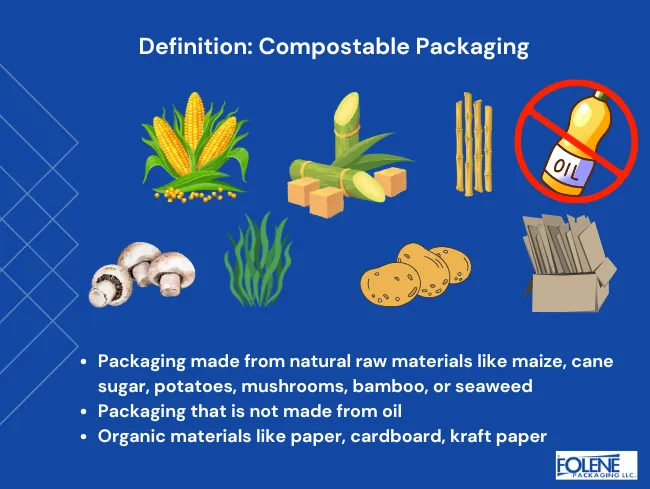

Types of packaging that are compostable include:

Bio-based plastics produced from cornstarch (maize), sugar canes, potato starch, wood pulp and other organic materials

Packaging made from natural raw materials like maize, cane sugar, potatoes, mushrooms, bamboo, or seaweed

Packaging that is not made from oil

Organic materials like paper, cardboard, kraft paper

Remember that when a material is 100% compostable, it is not recyclable. Compostable materials contaminate and interrupt the recycling process that is designed for non-compostable materials such as petroleum-based plastics. Recycling organic waste, food waste, or pet waste follows a different decomposition process from that of biodegradable plastic and compostable films.

Advantages of Composting Packaging

Composting discarded packaging offers several advantages:

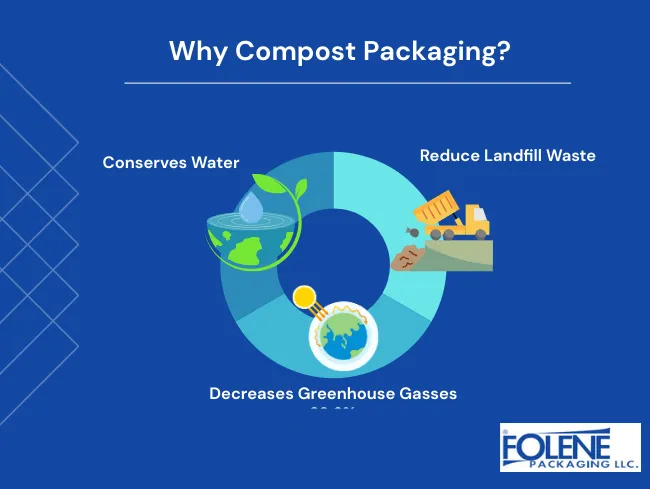

Reduces waste that must be processed at landfills and promotes a circular economy

Conserves water by furnishing a nutrient-rich, water-retaining soil that maximizes crop growth and minimizes water needed for irrigation

Decreases greenhouse gas emissions by ensuring better carbon isolation in soil and preventing methane emissions.

What Can Be Composted Throughout the Supply Chain?

Knowing what can be composted applies at all stages of the supply chain. Some materials can be composted at home, and some with a compost accelerator; some materials are commercially compostable only because they require an industrial composting machine. Understanding what to compost reduced the challenge we might encounter.

Who needs to process packaging by composting?

Manufacturers discard packaging from their absolute raw materials.

Shipping companies and importers may discard packaging provided by the manufacturer when repackaging goods for further distribution.

Suppliers and retailers discard outer packaging before selling goods to consumers.

Consumers and e-commerce end-users discard external and internal packaging material at the end of its useful life.

Choosing Compostable Materials – Look for Certifications

When choosing compostable products or packaging materials, certification from the Biodegradable Products Institute (BPI) or Compost Manufacturing Alliance (CMA) assures users they are really getting what they want.

Compostable products must meet strict standards for compostability and sustainability. Be wary of “greenwashing,” which involves false and misleading declarations about a supposedly environmentally friendly product.

How long does it take to compost? Look for “Certified Compostable” or “BPI Compostable.” All it takes to break down the packaging is 180 days or less in residential composting conditions and 90 days or less under commercial composting conditions.

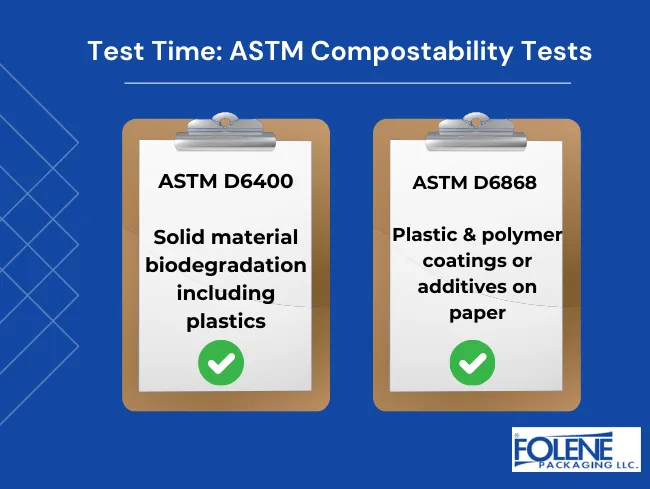

The American Society for Testing and Materials (ASTM) develops international consensus standards. For compostable products that can be aerobically composted in municipal facilities or industrial composting machines, two of these standards are:

ASTM D6400 – for solid material biodegradation, including plastics

ASTM D6868 – for plastics and polymers that are coatings or additives with paper

ASTM offers a free Standards Tracker service to track new or changed standards at the earliest possible stage to help you stay up-to-date.

10 Tips for Businesses: Choosing the Right Compostable Packaging

Here are some tips to help you choose the right compostable material for packaging in your business while focusing on your customer’s needs:

1. Make an impact with compostable materials

Ask yourself what your eco-values as a business are. Where do you want to make an impact?

2. Educate about the disposal of compostable items

Educate yourself, your employees, and your customers on the disposal of packaging at the end of its useful life. For example, Briko’s website has a detailed Packaging Disposal guide for clothing, footwear, and accessories to guide its customers.

3. Show you identify with composting benefits

To impress customers, make a gentle statement to your other business partners. Share your best practices indicating how you dispose of your packaging waste and how you support a circular economy. This is important, as the IBM Institute for Business Value discovered that 75% of consumers want to use environmentally responsible suppliers. More consumers have access to food waste, green waste, and organic waste through compostable waste programs.

4. What are compostable items made of?

Emphasize that compostable packaging is made from new (virgin) plant-based materials, unlike recycled materials, which are made from previously used materials. Often, customers find this more acceptable.

5. Investigate materials that are compostable

Before switching to compostable packaging or any other sustainable packaging, research the pros and cons of the different packaging options available. Learn how to choose the best packaging material for your purposes (whether recyclable, compostable, or reusable). Consider:

how long the packaging must endure until disposal

how strong it must be

how well it must protect your product

whether it needs to be rigid or should it be compostable, flexible packaging

6. Compostables for waste reduction

Make an effort to minimize waste in your business generally. Include the use of compostables in your waste reduction management plan. Apply for and use the compostable logo.

7. What are compostable initiatives that we can copy?

Select specific products that can use compostable packaging based on the highest suitability. That way, as you begin the journey, you will have the potential to have the fewest complaints. Look at what other similar companies have done and learn from their experience.

8. Compostable materials and your customers

Learn about your customers’ behavior. One way to do this is by conducting a customer survey. You can conduct an automated survey via email or social media to discover how stakeholders in the supply chain feel about recycling or composting packaging. Ask, “Do you have access to commercial compost facilities?” “Do you have a home compost system?”

9. Commercially compostable or home composting?

Find out which eco-friendly disposal option is easiest for your customers to use when handling and disposing of the packaging.

10. Do customers know what can be composted?

Since there is a lack of clarity about how to dispose of packaging correctly, pass on knowledge to your supply chain stakeholders. Educate all your supply-chain stakeholders by printing facts, instructions, and tips on packaging or on branded insert cards.

Folene Packaging Offers Packaging That Can Be Composted

Folene Packaging is an American company that provides European-grade polyolefin shrink wrap for manufacturers, suppliers, and retailers. The whole family of film wraps in the Folene Packaging brand, including the full range of Flxtite® and Ecolene®, are recyclable or compostable.

Ecolene® is fully biodegradable and compostable, supporting a naturally occurring breakdown process. Ecolene® can biodegrade in nearly any disposal condition without special handling requirements. This top-quality film wrap retains the same performance properties as regular polyolefin shrink film and does not begin to degrade until disposal.

Folene Packaging delivers customizable, printable shrink wrap and heat-sensitive packaging to help your business grow and stay on-brand while it is becoming more environmentally impactful.

Learn more about Flxtite® and Ecolene® as you discover what are compostable types of packaging and what can be composted from a business point of view.

What Are Compostable Materials FAQ

What Does Commercially Compostable Mean?

Commercially compostable types of packaging will break down within 90 days under commercial compost conditions, such as in an industrial composting machine. They are compostable meaning they are organic materials that can disintegrate naturally.

Biodegradable vs. Compostable: What is the Difference Between Compostable and Biodegradable?

Biodegradable and compostable are often used interchangeably, but they have different meanings.

Biodegradable materials can take hundreds of years to break down, while compostable materials break down in a matter of weeks.

Compostable materials are a more sustainable option than biodegradable materials.