As a supplier, you could drown in suggestions for different types of packaging because there are so many. As a manufacturer, you want to focus on what you are good at – producing and shipping items. So why does deciding which kind of packaging to use seem so complicated?

Packaging is ostensibly of lesser importance; when the product is opened, the packaging is simply discarded. However, as you learn about the intended purpose and function of the different types of packaging, you will be more knowledgeable and empowered to make informed decisions. This will enable you to optimize the packaging you use for your products.

The Definition of Packaging – Protect, Present, Predict

Packaging refers to the elements that protect and bundle together goods for transport, storage, and handling. “Packaging” is a general term that refers to the wrapping directly holding a product and any wrappings beyond, which protect the goods extensively. The packaging industry has developed different types of packaging to wrap and pack items – and suppliers need to be familiar with them to select the most effective and cost effective type of packaging.

Packaging protects the product until it is purchased, presents it to the consumer, which means it is a marketing tool, and, most importantly, allows the sender to predict the condition the goods will be in upon arrival to the end user.

3 Main Types of Packaging – But More Than One Way To Categorize

Packaging companies categorize packaging either by packaging material type or by function. While different packaging raw materials include glass, wood, plastic, paper, and natural materials, this post discusses packaging by function. The importance of packaging lies in the roles we expect it to fulfill, from delicate packaging for jewelry to a rigid corrugated cardboard box.

There are 3 main types of functional packaging. When packaging is classified by function, it is described as primary, secondary, and tertiary packaging. The packaging materials used for each type of packaging are relevant, but they vary from product to product. In these 3 packaging types, the “position” and function are fixed.

Let’s look at the different types of packaging:

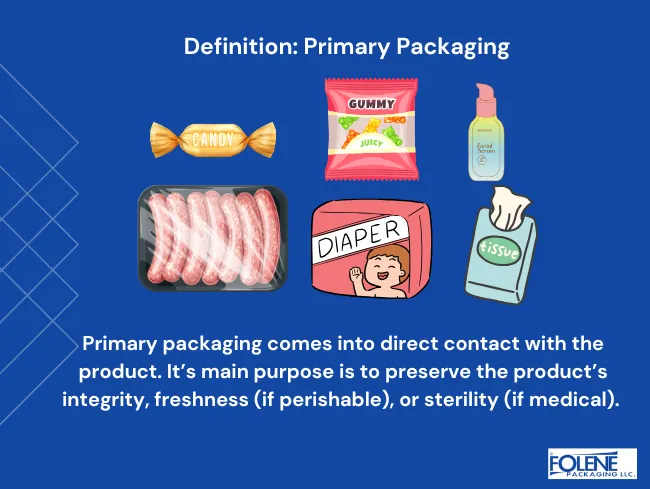

Primary Packaging

Primary packaging refers to the packaging that directly wraps the product itself. Sometimes, the primary packaging is discarded when the product is used (imagine apples wrapped as individual units), and sometimes, it is retained while the product is being used (imagine 100 tissues wrapped in a cardboard dispenser). Primary packaging comes into direct contact with the product and makes it look appealing to consumers. Food packaging and wrapping around food items and food products is often the primary packaging.

Primary packaging examples and materials

Primary packaging examples include protective shrink film, sweet wrappers, blister packs, and the cardboard box around a shaving machine.

Primary packaging materials are flexible plastic pouches, glass jars, tin cans, kraft paper, and recyclable plastic containers.

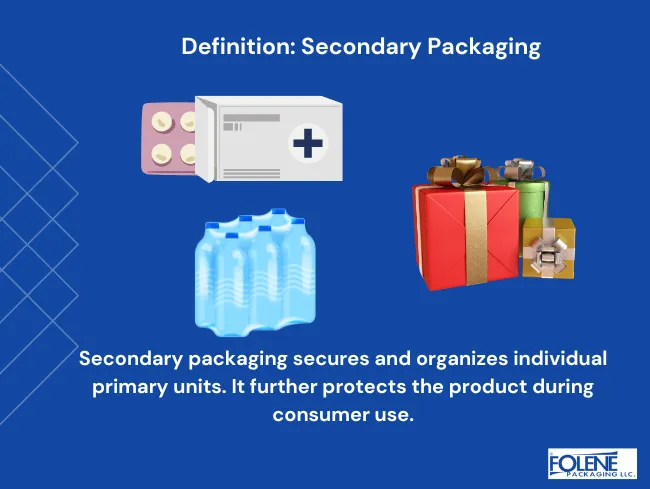

Secondary Packaging

Secondary packaging refers to packaging that secures and organizes individual primary units (think of the cardboard box around blister packs for medicine, shrink wrap around several medicine bottles, or rings around a six-pack). The secondary packaging is often retained until the product has been used, but is discarded sooner than the primary package. It has to be strong and long-lasting nevertheless, since the item might wait around until it is used.

Secondary packaging examples and materials

Secondary packaging examples are cardboard boxes, gift wraps, bubble wraps, ship-in-own container items, and plastic delivery envelopes.

Secondary packaging materials include bubble mailers, cardboard boxes, various types of shrink wrap, recycled paper pulp sheets, and foil packaging materials.

Tertiary Packaging

Tertiary packaging refers to packaging that protects the products during shipping. It is also called transit packaging. Think of pallet wraps and other tough packaging types that can withstand the bumps and scratches of handling until delivery. Tertiary packaging is always discarded right away as soon as the product arrives at a temporary or final destination. Tertiary packaging can be flexible or rigid, depending on the product.

Tertiary packaging examples and materials

Tertiary packaging examples are strong cardboard boxes, tough, puncture-resistant shrink wrap, or wooden freight containers.

Tertiary packaging materials include wood, metal sheeting, plastic films, corrugated cardboard boxes, and rigid plastic crates.

Different Needs, Different Types of Packaging: 8 Supply Chain Stages

Packaging means different things to different people along the supply chain. International supply chains are more complex, and e-commerce means packaging has become center stage. Primary and secondary packaging has become sleeker and more sustainable to keep up with eco-friendly customer expectations.

This is what packaging can mean to different collaborators along the supply chain:

1. Packaging Types at the Manufacturing Plant

Product packaging by manufacturers may or may not be branded since the parties, further along, will probably repackage and brand. Packaging materials must be resilient, reliable, and hold the product most safely as it begins its long journey to the end consumer.

Packaging will comprise multiple layers (primary, secondary, and tertiary packaging). It is important to investigate packaging materials that are space-economical and lighter. Amazon reduced avoidable waste in packaging by 36% per shipment by following its own FFP protocol.

2. Packaging Types at the Distributor

The distributor may open the external layers of the packaging (secondary and tertiary packaging) to add branding. That is why the primary packaging must be strong and tough to remain intact throughout this process. The distributor may have to dispose of the original secondary and tertiary packaging and add new, branded secondary packaging and protective tertiary packaging materials to secure the products as they continue on their journey.

3. Intermodal Marketing Company – No Packaging Types

This stage might include collaborators who handle shipping containers on behalf of manufacturers. Sometimes, they own the containers used, or they own a fleet of shipping trucks. They do not open any of the packaging, nor do they wish to do so. Suitable packaging for an intermodal company means reliable packaging that does not cause problems.

4. Packaging Types for Transportation

Products can be transported via ocean, rail, road, or air. Transportation is often subcontracted to external companies. Collaborators can reduce shipping costs by choosing light and streamlined packaging. No packaging will be opened; the transporting company wants the packaging to remain as it was when it left the container.

5. Warehouse and Distribution Center

The distribution center will act as the logistics provider, tracking which products will travel to different retailers or directly to the end user in the case of e-commerce. They also act as the holding space for product recalls, withdrawals, and product retrieval (where there are safety risks or design faults). The packaging needs for warehousing are: Packaging that is tough, transparent or clearly labeled; tertiary packaging that is reasonably easy to open; and secondary packaging that is strong and will not pop or snap open by itself.

For shipping and order fulfillment, packaging must be transparent secondary packaging and reasonably easy to open secondary and tertiary packaging; primary packaging must be absolutely integral, a type of packaging that can provide adequate protection yet allows products to be bundled or repacked for order fulfillment.

6. Retailers Deal With The Most Types of Packaging

Retailers unpack the products from the secondary and tertiary packaging and place them on the retail shelves in their primary packaging. Common packaging materials include pallet shrink wrap, plastic straps, or wood crates. The responsibility for the disposal of the packaging materials lies with the retailer. However, the EPR laws are changing to share the trash disposal burden. Packaging must be standard, reasonably easy to open, and crushable for streamlined disposal.

7. Brands to Consumers

Also known as direct-to-consumer (DTC) brands, these include online catalog orders. By selling directly to customers online, the brands bypass wholesalers and retailers. Apart from preserving all the profits for themselves, this allows the brands to influence the user experience. This is most noticeable in packaging, which can be branded from every angle. Primary packaging, of course, will be branded; the secondary packaging will also display the brand information prominently. Sometimes, the delivery van is branded, too, although it’s questionable if a van counts as packaging. Packaging must be elegant and convincing – not ugly and bulky – yet strong enough to protect the item inside.

8. Ships in Own Container (SIOC) Packaging

Door-to-door delivery from the company to the consumer needs integrity in packaging. E-commerce companies usually use this method of packaging and delivery. The product often meets other collaborators along the way unless it is a small family business, in which case there may be no other people in between. The shipping container is considered primary packaging, along with the other types of packaging.

Different Types of Packaging: Different Perspectives

8 Tips for Determining the Best Packaging Types for Suppliers

Suppliers who hire packaging experts to explain the best packaging options for their products are helping their supply chain to become more streamlined and efficient. Ultimately, it is an investment that will pay off in more ways than one.

There are many functions of packaging for suppliers to consider when planning which type of packaging to use for packaging: primary, secondary, tertiary, and onwards.

Choosing packaging:

Secure and durable – able to withstand various environmental challenges

Affordable and easy to use – to reduce costs and increase time efficiency

Readily available – to reduce lead times and improve supply chain efficiency.

Legally compliant – to meet regulatory requirements for industry standards and avoid fines

High quality – to protect the product and maintain customer satisfaction

Effective packaging design – for branding and marketing, for product protection

Allows product visibility – to showcase the product and to reduce returns and exchanges

Sustainable – to minimize environmental impact, to reduce waste, to meet green regulations

6 Ideas for Determining the Best Packaging Types for Consumers

At the beginning of the supply chain, manufacturers and suppliers should consider the end user’s needs and whether the packaging is eco-friendly.

When planning which type of packaging to use for primary, secondary, and tertiary packaging, consider the consumer:

Ease of opening – whether a penknife or scissors is required

Accessibility – for users living with a disability or child-proofing

Ease of disposal – whether containers can be dismantled or crushed

Cost – not to add on unnecessary expense

Durability – the packaging will last until the end of its useful life

Sustainability – to reduce the packaging footprint wherever possible

How Folene Packaging Provides One Material for 3 Types of Packaging!

Folene Packaging provides shrink wrap in a full range of gauges (thicknesses) to provide primary packaging (think of those apples wrapped as individual units!), physical secondary packaging for the exterior protection of products, as well as additional protection for tertiary packaging.

Folene Packaging’s packaging experts can advise you on the best options to suit your needs, whether primary packaging, secondary packaging, or tertiary packaging. Shrink wrap is one of the most space-effective and protective packaging materials available. It is flexible so it can wrap products of any dimension. Additionally, you can choose to use shrink wrap that is more heat sensitive or less heat sensitive, depending on the product you are wrapping. Ask to see our product descriptions.

Contact Folene Packaging today and ask about the types of packaging Folene Shrink Wrap products offer suppliers.

FAQs About Types of Packaging

What are 6 common functions of packaging?

Packaging serves many functions. Here are some of the main functions of packaging: 1. Physical protection: Packaging protects the product from damage and maintains product integrity. 2. Marketability: Packing products carefully ensures customer satisfaction. 3. Sanitization: Covers and boxes keep food and medications safe from contamination. 4. Grouping: Bundles together products for better organization. 5. Information: Packaging provides information about the product, such as ingredients and instructions. 6. Quality retention: Packaging helps to extend shelf life and maintain product quality.