Flxtite® proudly presents its latest addition to an expansive range of shrink-wrap options: Ecolene® AP-XPCR, possibly the answer for manufacturers, suppliers, and retailers to issues about packaging quality, waste disposal costs, packaging footprint reduction, and compliance with state and local laws!

Ecolene® AP-XPCR is made primarily from recycled material, which presents enormous benefits to everyone throughout the supply chain.

Ecolene® AP-XPCR offers users the same strengths as top-of-the-line cross-linked films.

In performance, Ecolene® AP-XPCR scores as highly as other high-quality polyolefin films!

Let’s learn more about the features of this innovative, sustainable film that incorporates a substantial amount of post-consumer content in its raw form.

What is post consumer recycled content?

Post consumer recycled content is the term used to describe products made partially or entirely using material that fulfilled its useful purpose and was discarded by consumers.

The raw material for recycled content is called “post consumer recyclate,” and it is processed at a waste recycling facility or sometimes a material recovery plant into “post consumer resin.” The resultant material is made into products. Plastics commonly suitable for post consumer waste recycling include PET, PP, and HDPE.

6 Improvements That Post Consumer Recycled Content Offers Manufacturers

As awareness of environmental care grows, manufacturers are acting on the need to reduce virgin material consumption. At the same time, they seek to reduce production costs – which include garbage disposal, compliance fees, and sometimes fines.

Post consumer recycled raw materials offer these benefits to manufacturers:

It helps businesses meet essential sustainability goals and reduce their impact on the environment. A certificate of recycling issued by the service provider can be displayed to inform the public of sustainability goals, documenting the waste that an organization recycles.

Improve relations with the 35% of the customer segment that requests environmentally friendly products and packaging and the 70% of customers who are even willing to pay more for products with sustainable packaging.

Allows companies to view using virgin materials as an avoidable expense, leading to overall financial improvements.

Post consumer recycled content (PCR) contributes to the circular economy and improves the supply chain in the larger picture. Post consumer recycled materials such as paper, plastic bottles, and aluminum cans become valuable once again.

Using post-consumer material facilitates state-level regulatory compliance. In California, for example, manufacturers can mitigate state-mandated eco-modulation fees. Several proposed laws and laws passed already are expected to change the way waste is handled. Manufacturers need to be ready.

Manufacturers of products using post consumer recycled plastic can benefit from reduced energy consumption. They can generate energy savings of up to 79%, and a side benefit of reduced greenhouse gas emissions, reduced by 67% at a minimum.

Manufacturers can save money on disposal costs, sending otherwise trash to recycling plants, and paying for less waste to be sent to landfills. Striving towards zero waste principles helps improve manufacturers’ efficiency – they can even create cashflows from their waste stream.

3 Types of Recycled Content

There are three types of recycled content. Products made available for consumers use come from the first type, post consumer recycled materials. Manufacturers who produce items with these post consumer materials must be able to provide recycled content certification stating how much post consumer content is incorporated in the items, which is usually expressed as a “post consumer recycled content percentage.” For example an item’s label might state: 40% total recycled content.

Post-consumer recycled content (PCR): Recycled material that was harvested from products consumers have already used or plastic packaging. Discarded materials are usually recycled for consumer use.

Post-industrial recycled content (PIR): Recycled materials that have been separated from the industrial waste stream during the manufacturing process. Usually reused in the industrial scene.

Pre-consumer content: Recyclable material from discarded items collected during production, including rejects and offcuts. Recyled for consumer or industrial use.

4 Challenges of Using Post Consumer Recycled Content

The greatest advantages of post consumer waste and post industrial waste are yet to come, as the infrastructure for reusing recycled object is still developing. Trellis Group (formerly Greenbiz) an online community supporting sustainability professionals, predict demand for post consumer plastics will increase by 5,000,000 metric tonnes by 2030.

By then professionals must resolve some of these issues:

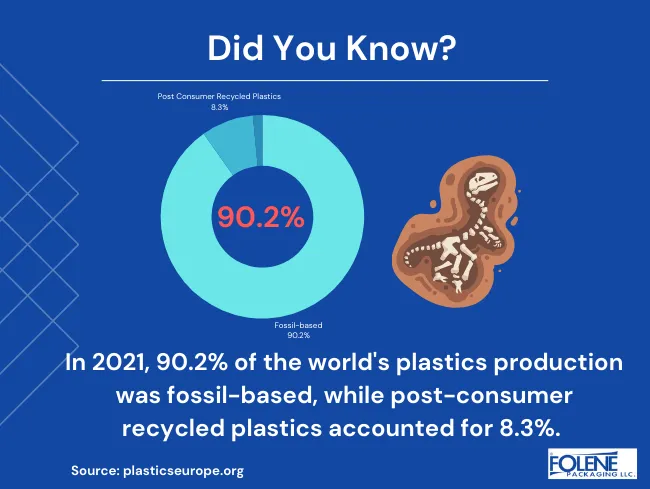

Not enough post-consumer materials are being collected, which indicates that the recycling infrastructure needs a major overhaul. The supply of post consumer plastics today is sufficient for less than 6% of demand.

Unless economies are applied to the way recycled content is processed, post consumer recycled material could be more expensive than virgin materials, making it difficult for companies to adopt.

Post consumer waste derivatives will be more challenging to produce and integrate into the regular plastic stream unless their properties are better understood.

Contamination, such as phthalates from the waste collection stage or flame retardants and heavy metals from the recycling process, and mixed materials in post consumer recyclate can make recycling and reusing the recyclate more challenging. Scientists report that crosslinking can help transform unmixable materials into useful, sustainable polymers.

Ecolene® AP-XPCR, Made with Post Consumer Recycled Content Reduces the Global Packaging Footprint

Flxtite® has successfully developed a new shrink wrap that contains a substantial percentage (50-60%) of post consumer content. This enables the ecologically conscious to participate in the global move towards reducing the use of virgin materials and reducing waste while providing an excellent product.

This cross-linked polyolefin film does not compromise. It features high-quality strength, yield, and shrink qualities proven by ASTM testing. As an example, Ecolene® AP-XPCR shrink film of 75 microns has a density of 0.92 gm/cc and a yield of 40,000 sq. in./lb. It also boasts a haze of just 2.5% and an impressive gloss rate of 135%. Ask to see the rest of the specifications, or test it yourself for your product’s intended use.

Reach out to Folene Packaging today to discover how your production plant can benefit from the new recycled wrap with post consumer recycled content.